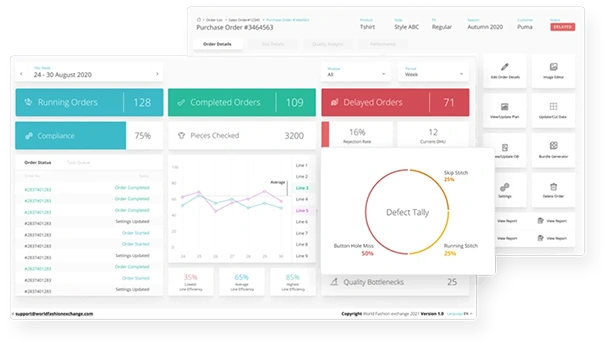

WFX Smart Factory is a powerful, modern Manufacturing Execution System (MES) solution for fashion businesses. It is designed to increase shop-floor productivity for fashion manufacturers, reduce costs, and improve quality control on the factory floor.

Trusted by 600+ Businesses:

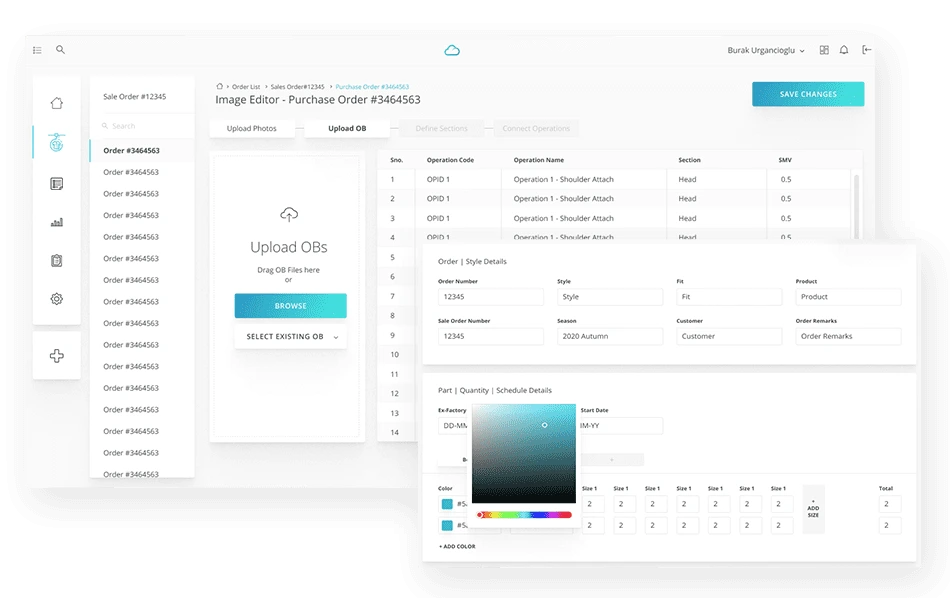

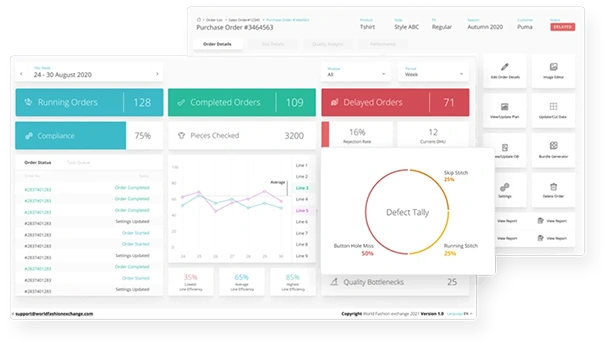

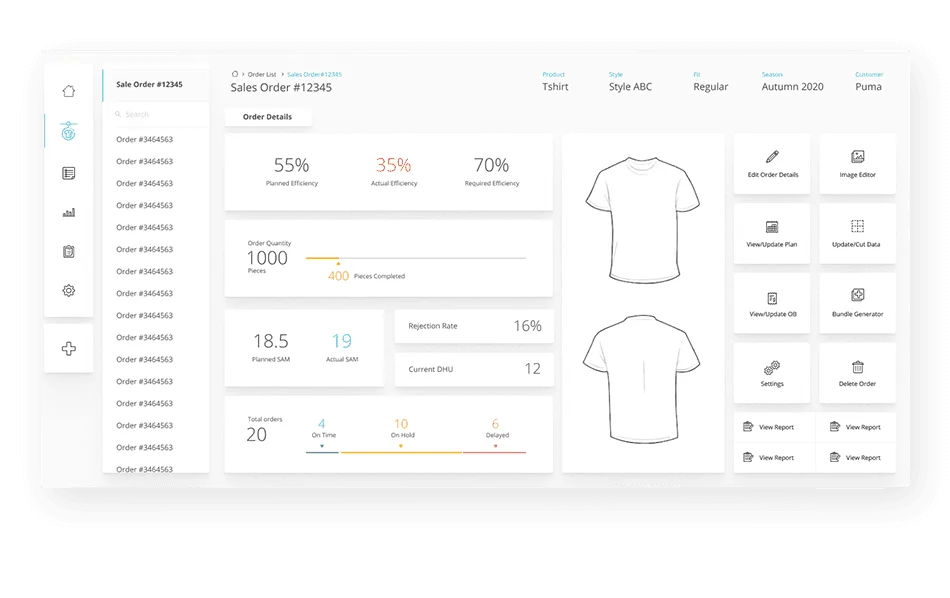

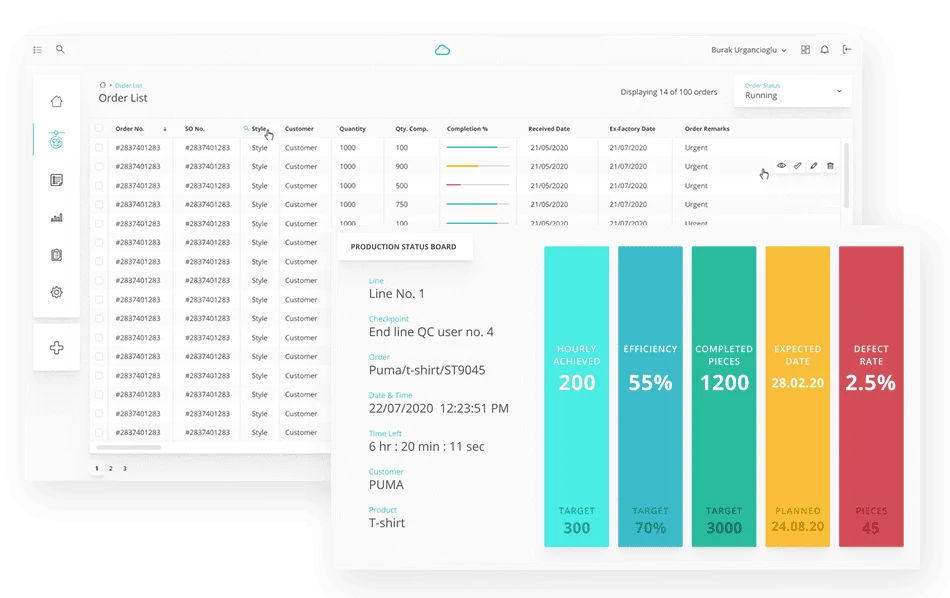

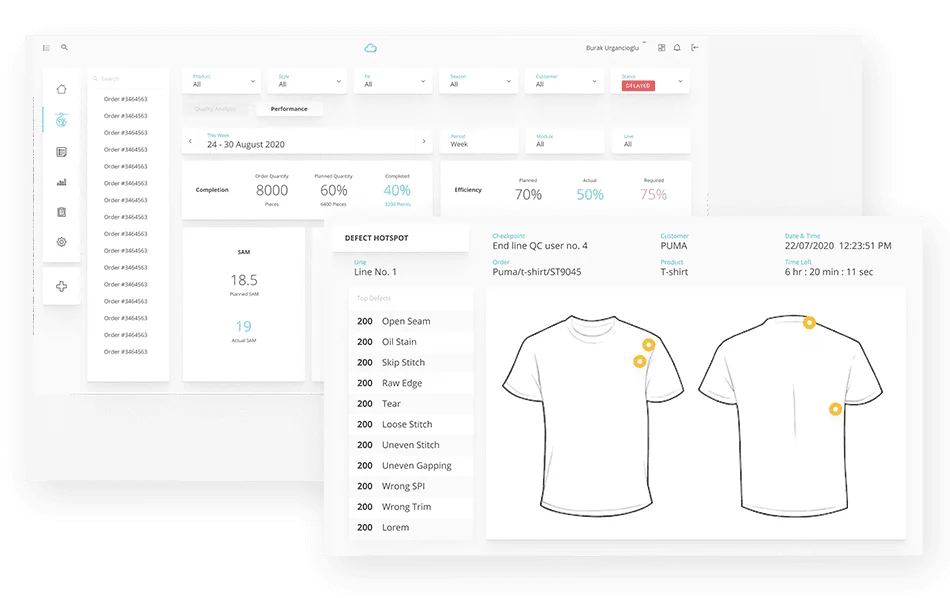

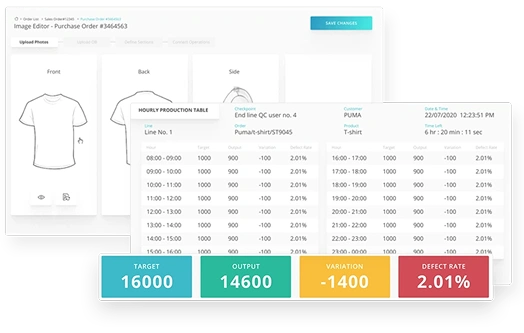

WFX Smart Factory provides an intelligent system to fully digitize floor production. Using a central MES, it enables you to plan, execute, track, and optimize every step of your apparel production.

Plan

Increase Output through Live Production Control

Easily Identify Product Defects in Real-Time

Access Actionable Insights to Optimize Production

Foster Accountability with Live Performance Data on TV Screens

Execute

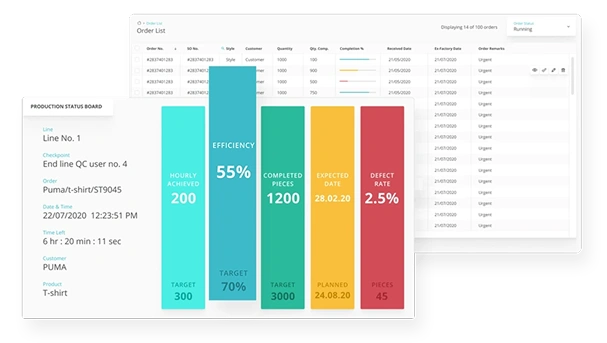

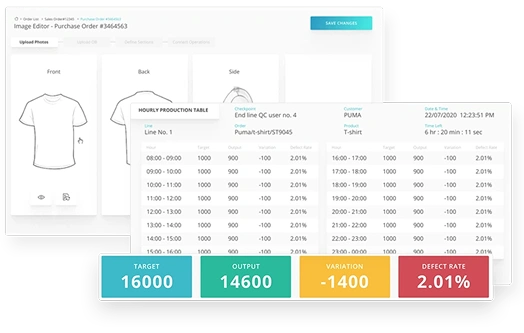

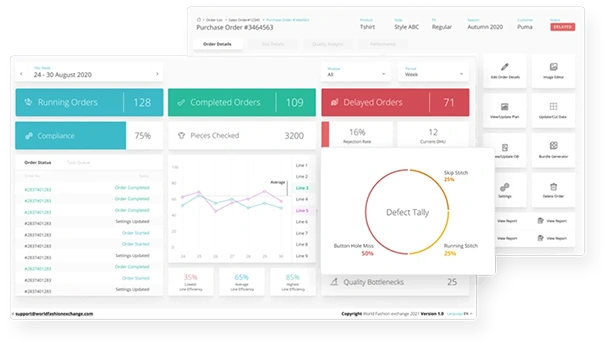

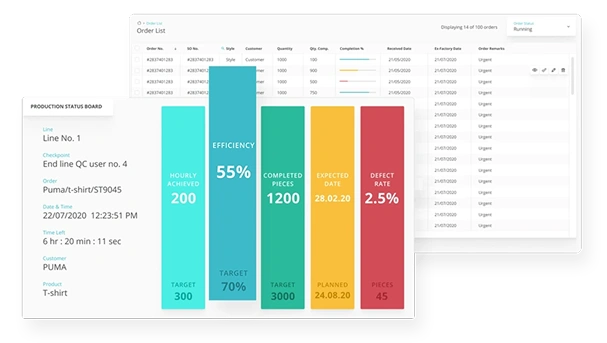

Increase Output through Live Production Control

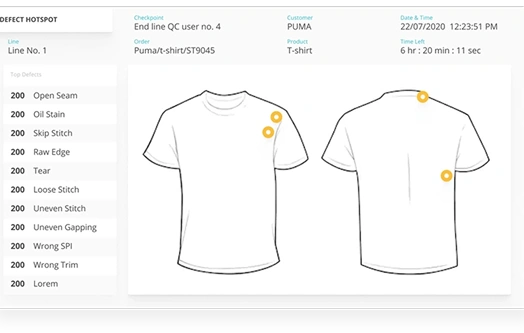

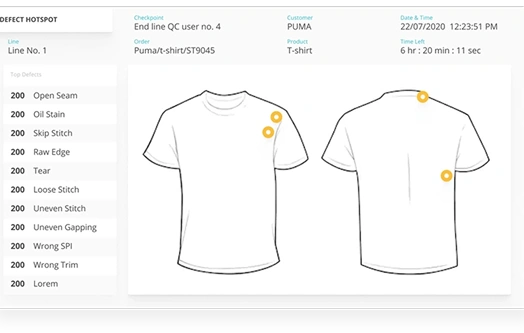

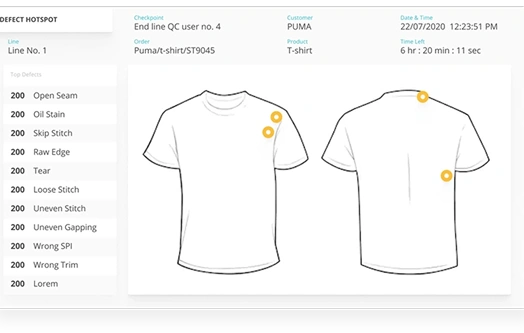

Easily Identify Product Defects in Real-Time

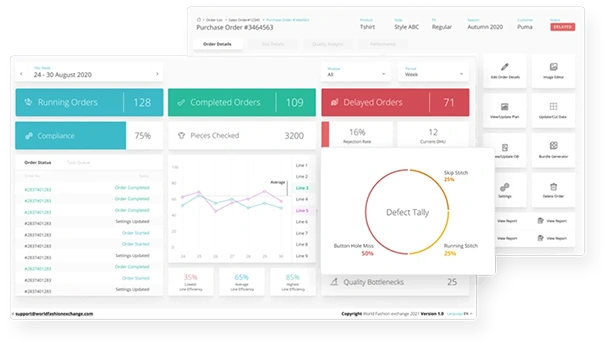

Access Actionable Insights to Optimize Production

Foster Accountability with Live Performance Data on TV Screens

Track

Increase Output through Live Production Control

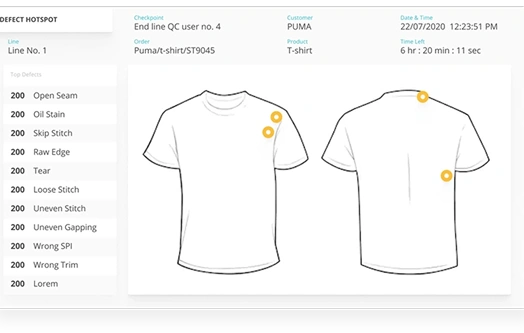

Easily Identify Product Defects in Real-Time

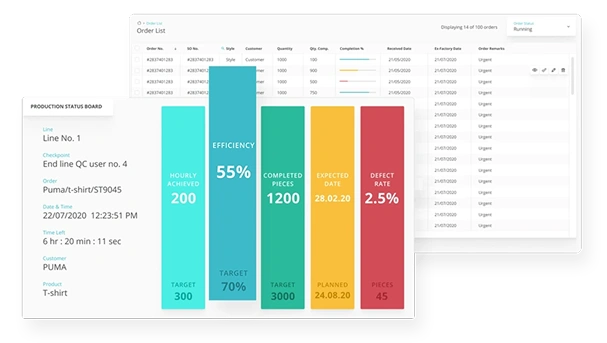

Access Actionable Insights to Optimize Production

Foster Accountability with Live Performance Data on TV Screens

Optimize

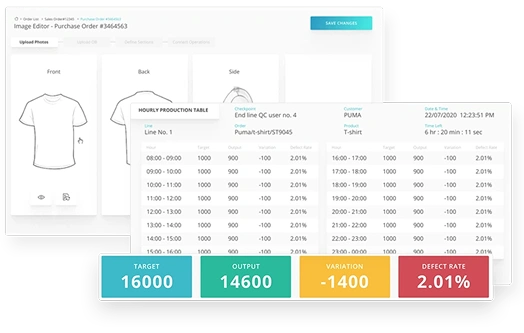

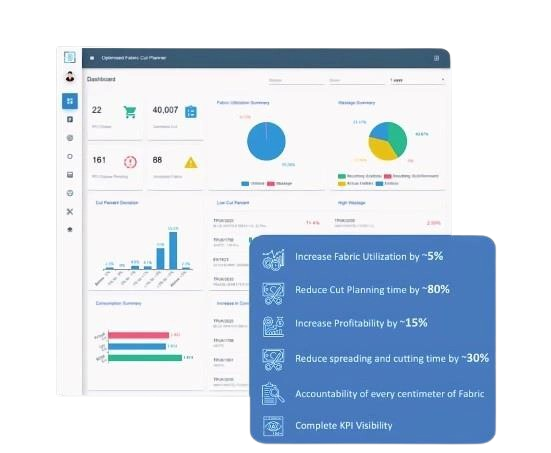

Reduce Fabric Waste and Automate Processes with Cut Plan

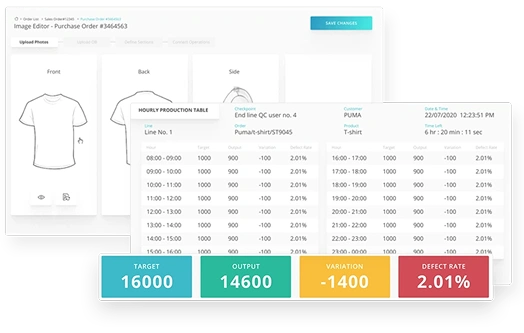

Increase Output through Live Production Control

Easily Identify Product Defects in Real-Time

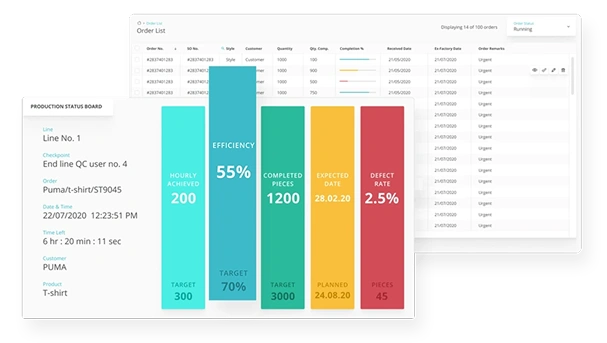

Access Actionable Insights to Optimize Production

Foster Accountability with Live Performance Data on TV Screens

For full visibility on the shop floor, digitize your manufacturing with WFX MES, the ultimate smart factory solution :

Message us for any queries

Don't find an answer to your question here?Contact us directly

What is smart factory manufacturing?

Smart factory manufacturing is a modern production approach that leverages advanced technologies such as automation, the Internet of Things (IoT), and Artificial Intelligence (AI) to create a fully integrated and automated production system. It is a digital transformation of traditional manufacturing processes that allows for increased efficiency, productivity, and quality control.

What are the benefits of smart factory for manufacturing?

The benefits of smart factory for manufacturing include increased efficiency, productivity, and quality control, reduced downtime, improved worker safety, reduced material waste, and increased customer satisfaction. Smart factories enable companies to make data-driven decisions, optimize production processes, and respond quickly to market changes.

What technologies are used in a smart factory?

Smart factories use a range of technologies including automation, robotics, IoT sensors, AI, big data analytics, cloud computing, and cybersecurity. These technologies work together to create a connected and intelligent production environment.

What are some challenges of implementing a smart factory?

The challenges of implementing a smart factory include the high cost of implementation, the need for technical expertise and devices, data security concerns, and resistance to change from workers who may need to learn new skills or adapt to new technologies. It can also be challenging to integrate legacy systems with new technologies.

How can a company get started with implementing a smart factory?

A company can get started with implementing a smart factory by first assessing their current production processes and identifying areas that can be improved. They should then develop a clear roadmap for implementation, including identifying the necessary technologies and infrastructure, setting up a pilot project, and gradually scaling up to full implementation. It is also important to engage employees and provide training and support to ensure successful adoption.

Why should fashion manufacturers use WFX Smart Factory?

WFX Smart Factory helps fashion manufacturers optimize production processes, increase productivity, and improve product quality. The software helps compare planned vs actual performance, ensuring production targets are met on time. It creates a culture of self-accountability by livestreaming performance insights and quality control dashboards to TV displays, iPads and smartphones.