Natively built on 100% cloud technology so you get automatic updates of the latest features, functionalities and security patches, without any manual intervention or downtime!

The solution has been developed by textile industry experts to help companies of all sizes grow profitably and run sustainably.

Whether it's a growing enterprise or a multinational conglomerate, WFX scales alongside your textile business operations to maximize productivity across all functions.

The ERP integrates every aspect of your textile manufacturing operations improving the user experience with seamless accessibility, adaptability and real-time data analytics-based on years of research.

WFX’s ERP Software for textile industry offers an extensive suite of industry-specific modules, meticulously designed to cater to every aspect of textile manufacturing and management.

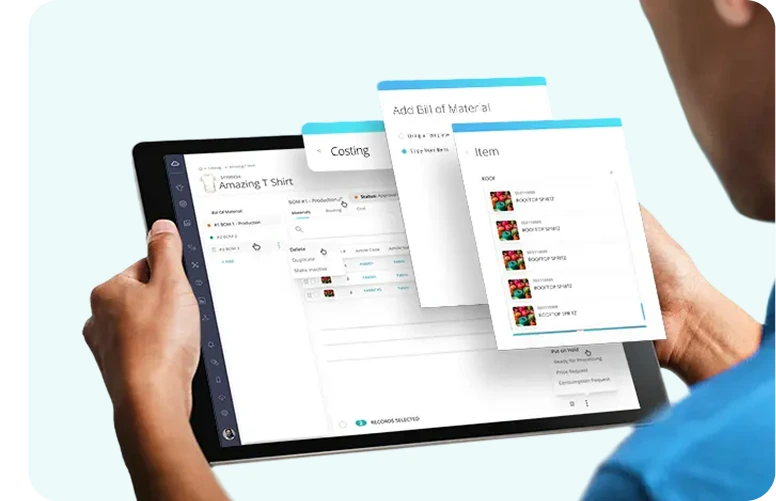

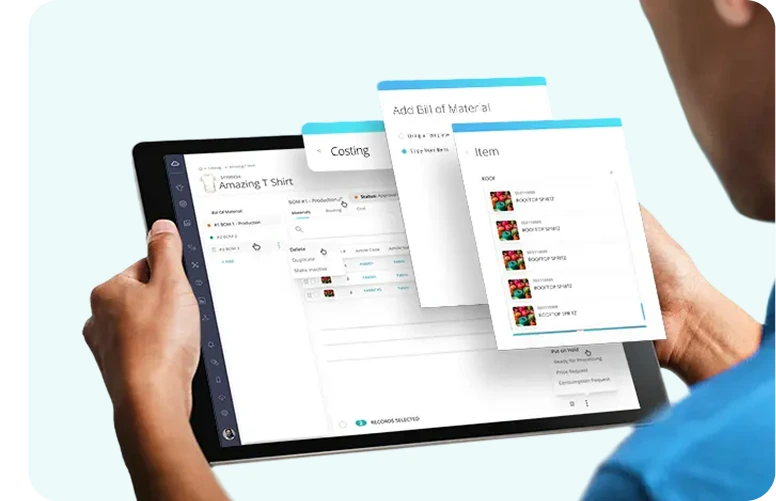

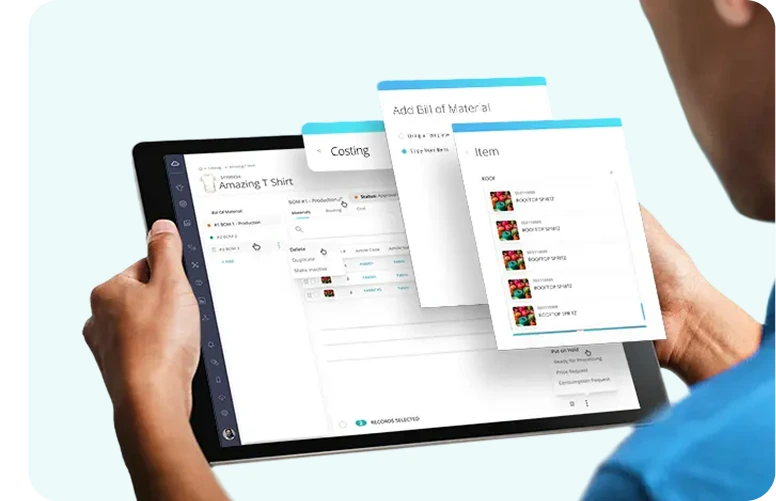

Gauge the financial impact of raw materials, labour, and overheads with precision, ensuring optimal costing for maximized profits.

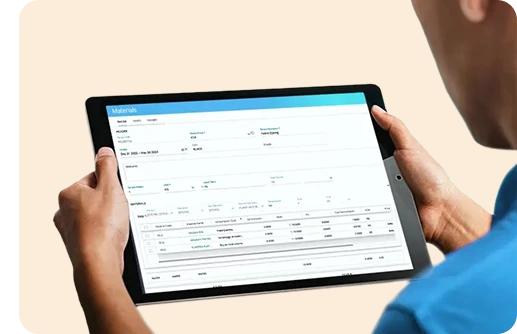

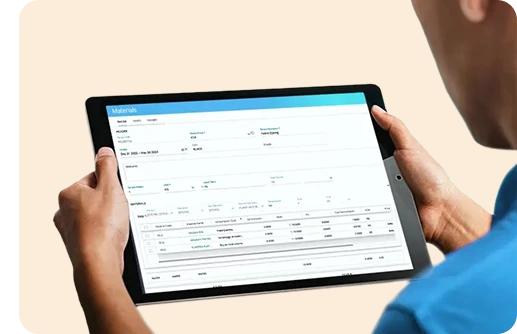

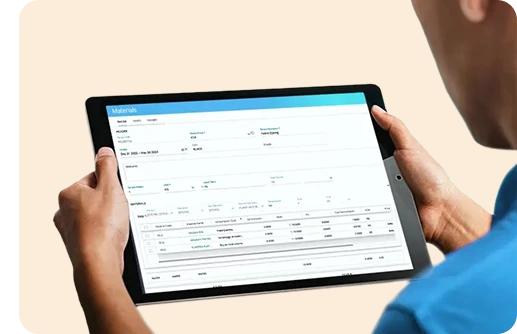

Centralize and manage a robust database of fibres, yarns, and fabrics.

Efficiently define and manage textile manufacturing operations.

Handle recipe details with precision for each colour variant.

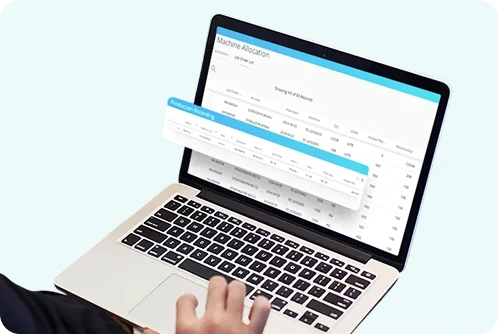

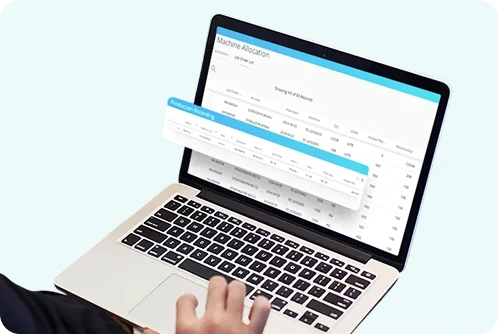

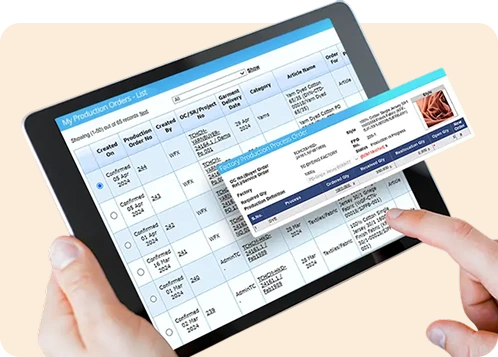

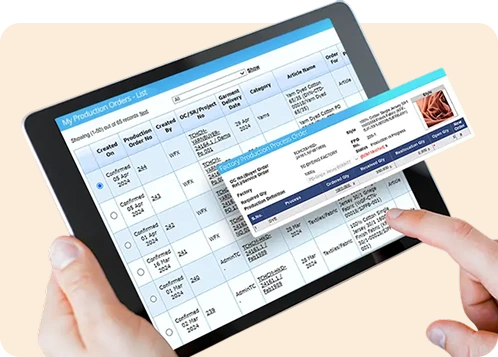

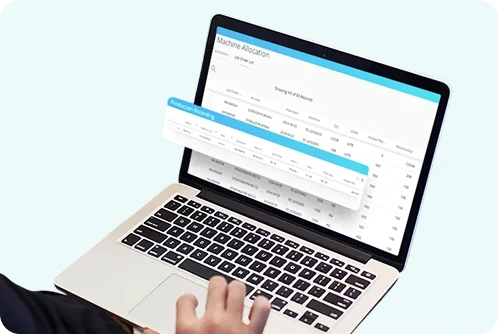

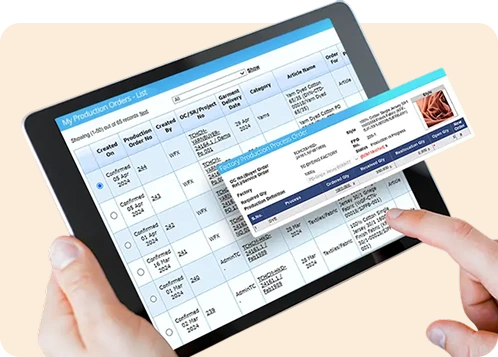

Optimize production workflows and processes.

Streamline the fabric sampling process to ensure quality and consistency.

Enhance sales order efficiency and accuracy.

Strategically plan and manage material requirements.

Efficiently manage procurement by keeping track of purchase orders, supplier performance, and inventory levels.

Maintain high standards of inventory management and quality control.

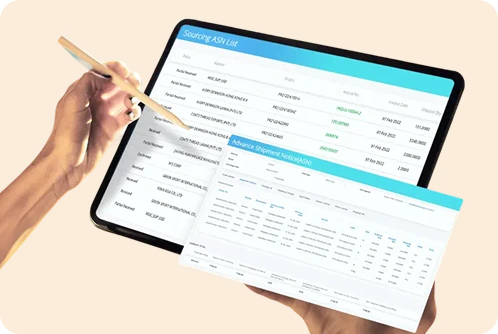

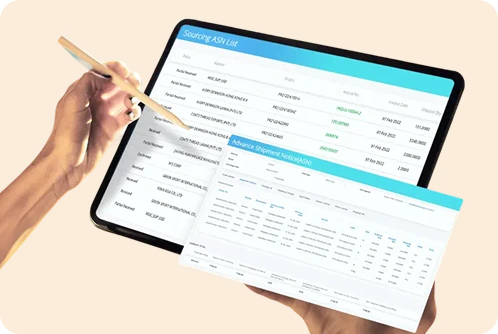

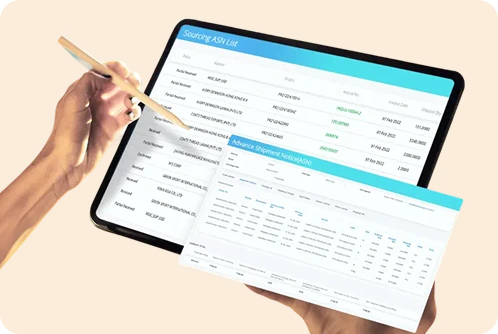

Effectively manage both inbound and outbound shipment processes.

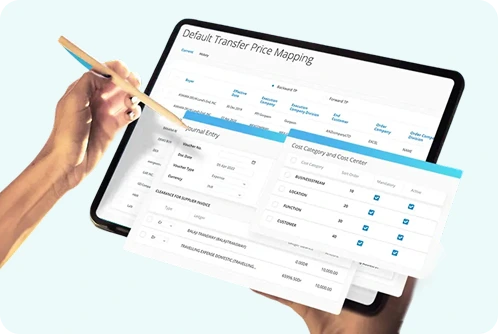

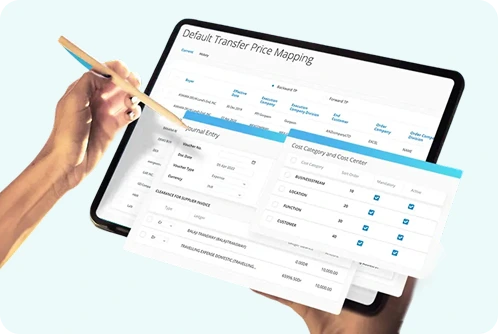

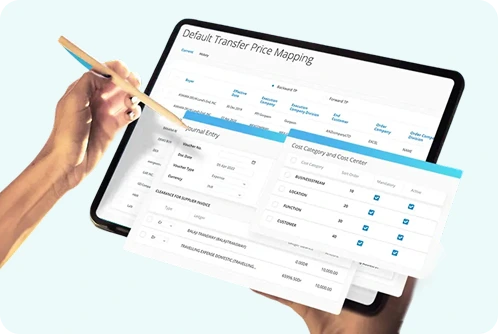

Achieve comprehensive financial oversight and reporting.

Capture orders, track shipments, and monitor sales performance to forge stronger customer relationships and drive profitability.

Gauge the financial impact of raw materials, labour, and overheads with precision, ensuring optimal costing for maximized profits.

Centralize and manage a robust database of fibres, yarns, and fabrics.

Efficiently define and manage textile manufacturing operations.

Optimize production workflows and processes.

Streamline the fabric sampling process to ensure quality and consistency.

Enhance sales order efficiency and accuracy.

Handle recipe details with precision for each colour variant.

Strategically plan and manage material requirements.

Efficiently manage procurement by keeping track of purchase orders, supplier performance, and inventory levels.

Maintain high standards of inventory management and quality control.

Effectively manage both inbound and outbound shipment processes.

Achieve comprehensive financial oversight and reporting.

Capture orders, track shipments, and monitor sales performance to forge stronger customer relationships and drive profitability.

Scale faster and smarter with a modern ERP that:

WFX Textile ERP offers a plethora of tangible benefits, making it an indispensable tool in the textile industry:

WFX offers a vertically integrated ERP solution from garment to textile manufacturing for better visibility and efficient decision-making leading to seamless information flow and informed business strategies.

Efficient decision-making processes enabled by a single integrated database for all business processes, leading to seamless information flow and informed business strategies.

Enhanced product development control with all product and material information managed in one system.

Reduction in operational costs, increase in efficiency, which leads to improved profit margins and competitive advantage.

Efficient decision-making processes enabled by a single integrated database for all business processes, leading to seamless information flow and informed business strategies.

Increased customer satisfaction and retention, and growth in sales due to improved on-time delivery and order accuracy.

Mitigation of production bottlenecks, enhancement of efficiency across operations, ultimately improving reliability, credibility, and profitability of the business.

Users can dive right in without extensive training, saving time and improving productivity while still enjoying a powerful user experience.

Each client gets a personalized solution that matches their unique efficiency needs ensuring maximum ROI from the textile industry software implementation.

Explore articles, news updates and expert content from the WFX team!

Discover how ERP (Enterprise Resource Planning) systems are transforming the textile industry, streamlining processes, and driving efficiency for a competitive edge.

Read More

Discover how smart factories are transforming textile manufacturing with automation, AI, and IoT to boost efficiency, reduce costs, and promote sustainability.

Read More

Discover the 5-step SOCOI strategy to help garment & textile manufacturers drive digital transformation, boost efficiency, and stay competitive in the modern era.

Read MoreMessage us for any queries

Don't find an answer to your question here? Contact us directly

What sets WFX Textile ERP apart from other ERP solutions?

WFX ERP stands out as an ERP for textile and manufacturing industry. It’s tailored to industry-specific needs with modules like Production Management, Lab Dips, Recipe Management, Fabric Sampling, and more, streamlining textile business operations.

What kind of support can I expect during and after the implementation?

We offer comprehensive support during and after implementation with our ERP for textile industry. This includes assistance with system setup, data migration, user training, and ongoing technical support. Customer support teams are available 24/7 to help you resolve any technically issues promptly.

Can WFX Textile ERP integrate with my existing applications and systems?

Yes, WFX’s textile manufacturing software is designed to help you manage operations in multiple business locations, languages, units of measurements, tax situations, and support transactions in multiple currencies.

Is WFX Textile ERP a cloud-based or on-premise solution?

Our ERP software for the textile industry is a 100% cloud-based solution that you can access right from your browser. It gives you flexibility, anywhere access, and eliminates maintenance costs.

How scalable is WFX Textile ERP?

WFX's textile manufacturing ERP software is a highly scalable solution, designed to adapt to your business's growth and evolving requirements. As your company expands, the system can seamlessly accommodate additional users, departments, and functionalities.

Can WFX Textile ERP help with regulatory compliance in the textile industry?

Yes, we have designed an advanced traceability and sustainability solution designed to help all fashion businesses visualize their global supply chain, manage certifications, audit statuses and communicate compliance with buyers. The solution integrates seamlessly with our ERP for textile and apparel industry—giving you access to accurate reporting and complete visibility.

Can WFX Textile ERP handle multiple locations and currencies?

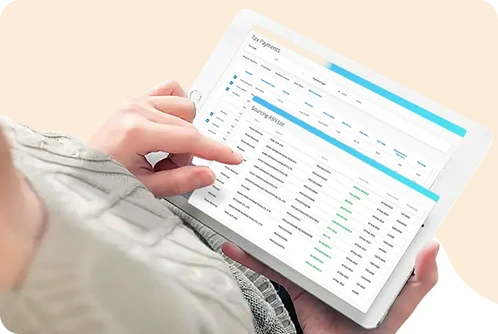

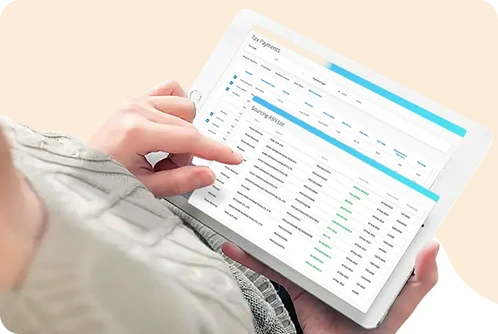

Yes, WFX Textile ERP is designed to help you manage operations in multiple business locations, languages, units of measurements, tax situations, and support transactions in multiple currencies.