Why tailoring your PLM software to your industry is so important

Introduction

Every industry has unique challenges. A software product that thrives in one industry may be completely inappropriate for another if it’s not tailored to that specific industry’s circumstances.

The supply chain structure and production stages of an industry determine the Product Lifecycle Management or PLM software lifecycle. Different industries have different needs from their PLM software lifecycle due to various factors. Some differences could be due to the variance in the types of materials used, the number of life cycle stages, the information management systems they use, or the scale at which a company operates.

For instance, a canned goods retailer has very different business system requirements from those of an apparel brand. That’s why they need a customizable, industry-specific PLM system which works effectively for their functional needs.

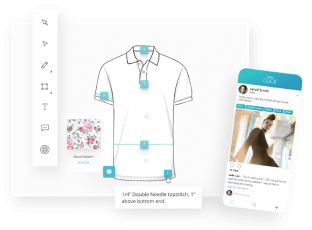

On the other hand, companies operating in similar sub-industries such as fashion, beauty, lifestyle or consumer goods tend to have similar product development processes as they all deal in products with a similar lifecycle. They also have the same efficiency and transparency requirements! Therefore, these businesses could benefit from using the same type of PLM software, such as WFX Cloud PLM.

When you’re choosing a solution for your business, you want the best bang for your buck. But how do you know if your software is ‘good?’ How do you know if it will work for your business? The answer lies in the details — specifically, how well it’s tailored to your industry.

How can you tell if a PLM system is tailored for your industry?

Want to know if a PLM is right for you or not? Start by asking questions like:

- Is the system used by companies in your industry already?

- What are the different departments you need to support in your company?

- Does it facilitate seamless collaboration between all your internal and external teams?

- Can you track the entire product lifecycle using the PLM?

- Does it allow you to store, manage, and search your product data efficiently?

- What information output formats do you need? What output options do you have?

- Has the PLM software system implemented optimal data security measures?

- Does the system offer change management tools relevant for your business?

If you’re in an industry that sees rapid innovation, you need a PLM that allows changes without having to start over from scratch. You need your workflow management software to be agile enough to adjust to sudden change without much friction.

5 reasons why you should look for industry-specific software

1. Quick And Seamless Software Integration

Everyone wants a beautiful, user-friendly product, but when it comes to exchange formats, data management and overall integration, not all systems are created equal. Most industries use specific software programs for product development processes – like CAD, Sketch Up, Adobe Suite, and so on. These may be similar in certain industries like apparel, outdoor gear, furnishing, food & beverage, cosmetics—where same or similar integrations can do the job.

What you need to look for is a solution that lets you cross-manage files across all relevant formats to avoid file conversion delays. This should be as easy as a drag and drop!

2. Personalized Data Intelligence & Management

Another reason to use a industry-specific PLM systems is to be able to find data quickly and easily. Less time spent on product data management (PDM) and data entry means more time to work on creative work. If you work in a consumer facing industry like apparel, food or footwear, you’ll want a visual-driven PLM where you can see and manage product data through pictures.

The PLM should give you multiple product views and information filters tailored to your industry’s requirements. Less time spent on searching for information means more time to focus on expansion and growth.

3. Updated With YOUR Industry’s Specific Trends

Having an outdated, rigid system that doesn’t meet your needs can be frustrating. The PLM provider you work with should know, understand and embrace industry-specific trends. For example, if you manufacture electronics, then your PLM system should have a provision to track the tech advancements in the industry. Similarly, if your domain is fashion, your PLM system should be able to keep track of fashion trends such as colors or styles.

In today’s scenario, where most enterprises are choosing to implement digital tools such as Artificial Intelligence (AI) and Internet of Things (IoT), the PLM system should embrace and stay updated as per industry-specific trends. A true PLM suite should offer scalability, flexibility and adaptability for whatever changes come next for your company or industry.

4. Aligned To YOUR Quality Control & Inspection Processes

The PLM system should be pre-fitted with your industry’s quality inspection and certification requirements. For example, the aerospace industry may require a manufacturer to keep a 2D paper drawing for every part produced. In the fashion industry, quality inspection might need to comply with specific tolerances for specific seams. If you’re using a PLM system that’s not tailored to your market, you may not have an efficient way to manage these documents or measurements.

If your company operates in multiple countries or regions, then chances are that you may also need to comply with different quality standards. The best PLM systems give you the flexibility to add new standards and workflows without disrupting the overall system.

5. Production Tracking Suited To YOUR Product Portfolio

A complex product portfolio can require more functionality than an average-sized company’s needs. The ability to spin up custom solutions around specific needs is one of the advantages of working with specialists in PLM over buying off-the-shelf software. For example, if your company makes one product, you may not need a complex materials management system. However, if you make multiple products, you will probably need cloud-based systems that can handle the variability in your business.

If you manage multiple factories spread across the country or around the globe, a solution built around physical inventory storage locations could get in the way of your operations.

Conclusion

How good or bad a Product Lifecycle Management solution often depends on how well its tailored to your industry. This is important because each industry has its own distinct characteristics. Discovering these characteristics and then building a system to support them will make your system more effective.

Want to figure out which PLM should you choose? Talk to our experts to ascertain if WFX PLM is right your business