Trusted by 600+ Businesses

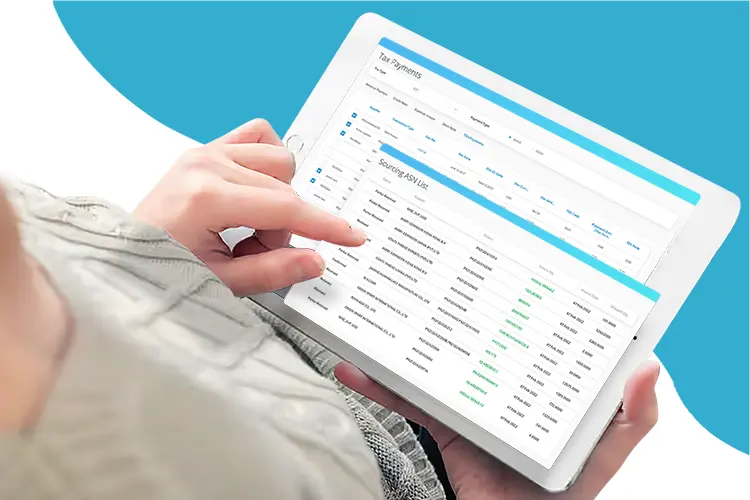

A Modern System Designed by Industry Experts

Key Modules

WFX’s ERP Software for textile industry offers an extensive suite of industry-specific modules, meticulously designed to cater to every aspect of textile manufacturing and management.

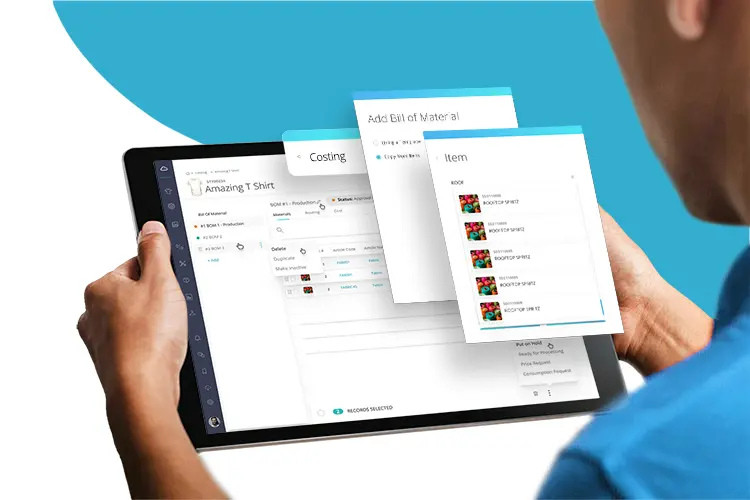

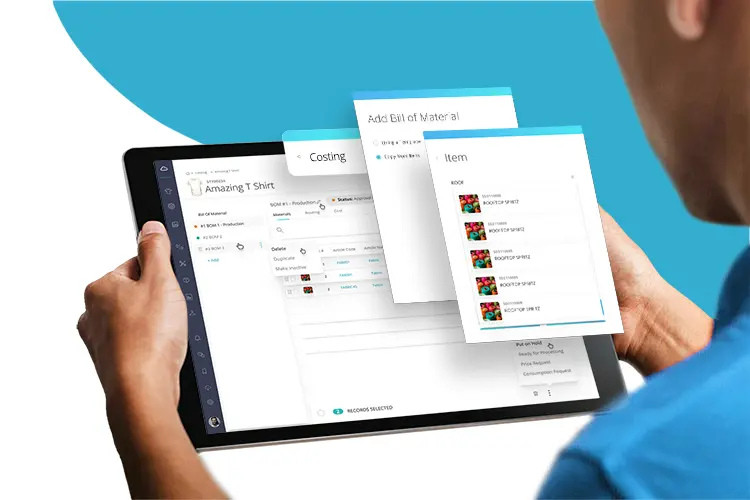

Gauge the financial impact of raw materials, labour, and overheads with precision, ensuring optimal costing for maximized profits.

- Determine accurate, real-time costs of raw materials, labour, and overheads.

- Utilize comprehensive expense tracing and allocation for precise cost management.

- Establish optimal costing parameters for maximized profit margins.

- Understand true production costs for strategic pricing and gaining competitive advantage.

Centralize and manage a robust database of fibres, yarns, and fabrics.

- Create detailed, configurable records for each product type.

- Develop comprehensive Fabric Tech Packs, encompassing product groups, sub-categories, counts, construction, GSM, and various units of measure.

- Streamline and maintain accurate costing for yarns and fabrics.

Efficiently define and manage textile manufacturing operations.

- Detail process operations and sub-operations.

- Calculate production time and cost components for each sub-process.

- Record and analyse process/operation SMV and SMV rates, along with process wastages and operation losses.

- Map specific machines to each sub-process and define operational sequences.

- Develop multiple routing masters, tailoring operation attributes for efficiency, time, productivity, and cost.

Handle recipe details with precision for each colour variant.

- Maintain a detailed recipe master for each colour and optimize lap dip processes for fabric color consistency.

- Register and catalog multiple approved recipe versions for flexibility and accuracy.

- Manage and create lap dip-wise recipes to accurately calculate recipe costs.

- Streamline the approval process based on buyer requirements.

- Manage dyes and chemical consumption calculations.

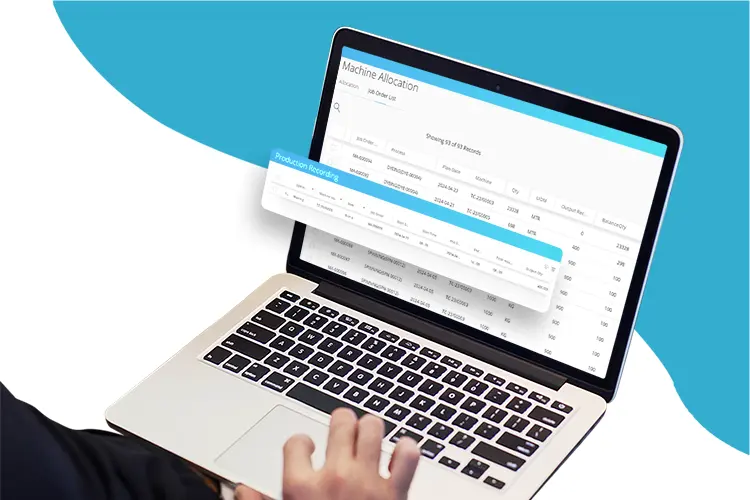

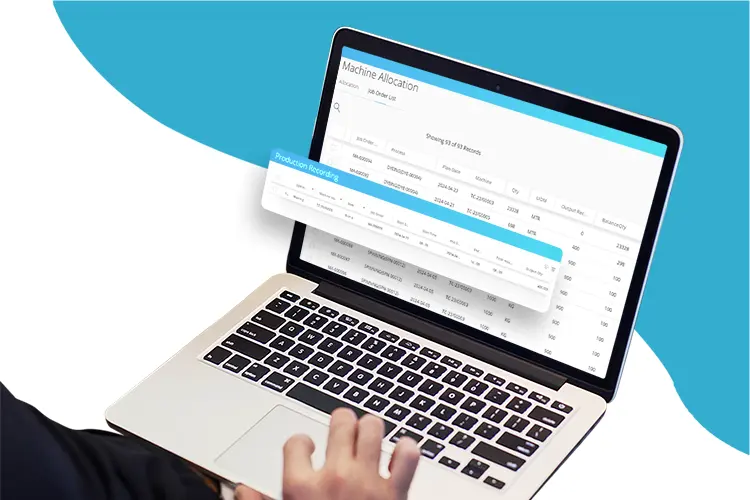

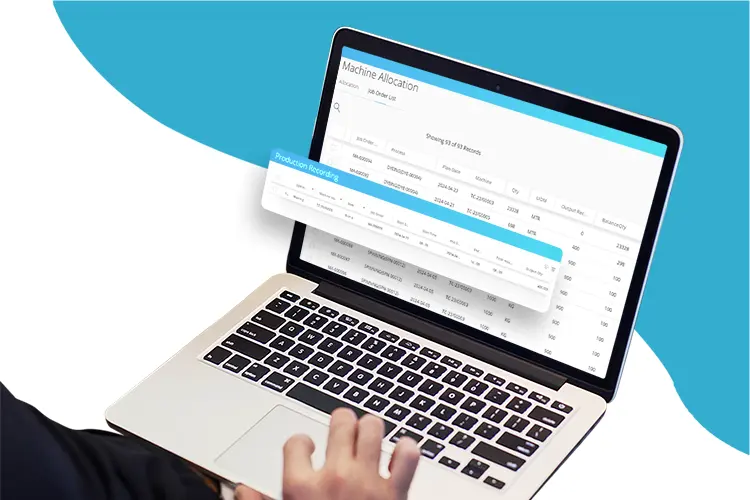

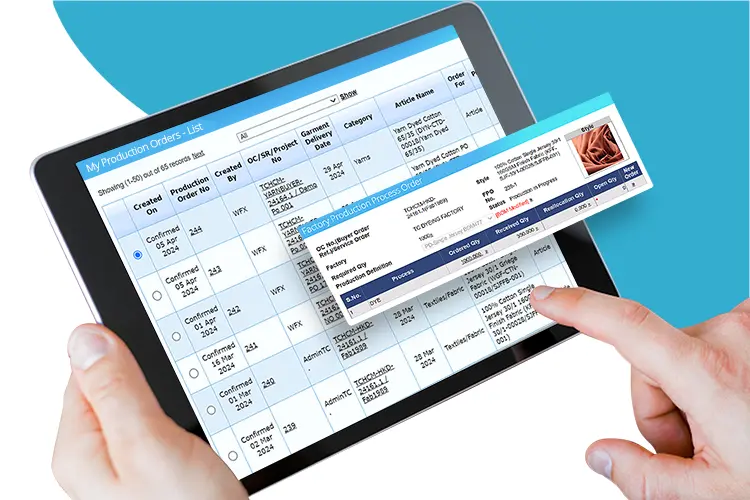

Optimize production workflows and processes.

- Seamlessly create and integrate work orders into production planning.

- Monitor and manage the status of work and quantity orders in real time.

- Schedule factory production orders effectively, attaching relevant production routings.

- Enhance lot/batch traceability with efficient roll selection for LOT number creation.

- Allocate machines strategically for individual and combined job orders.

- Record detailed information on machine output, including shift and operator details.

- Analyze material consumption at each process stage for variance management.

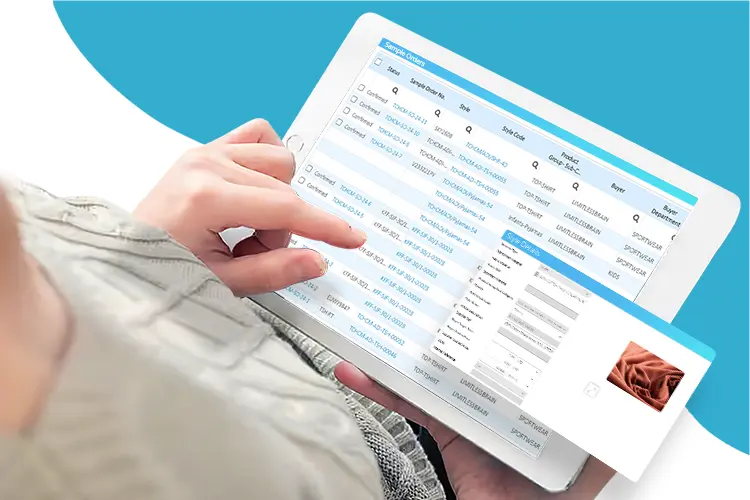

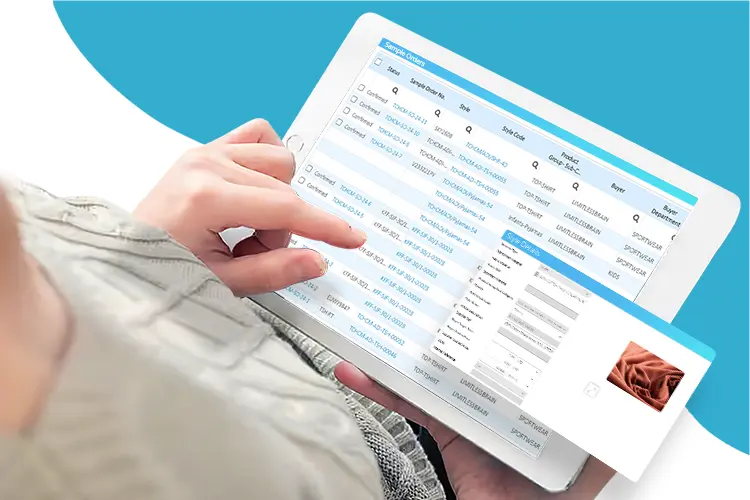

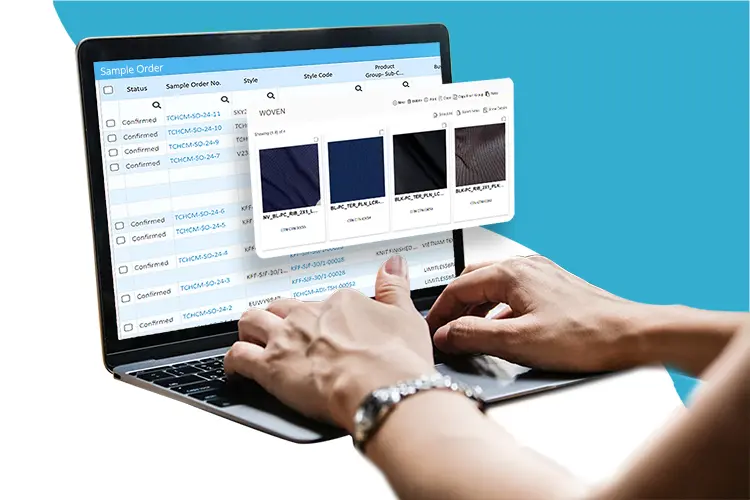

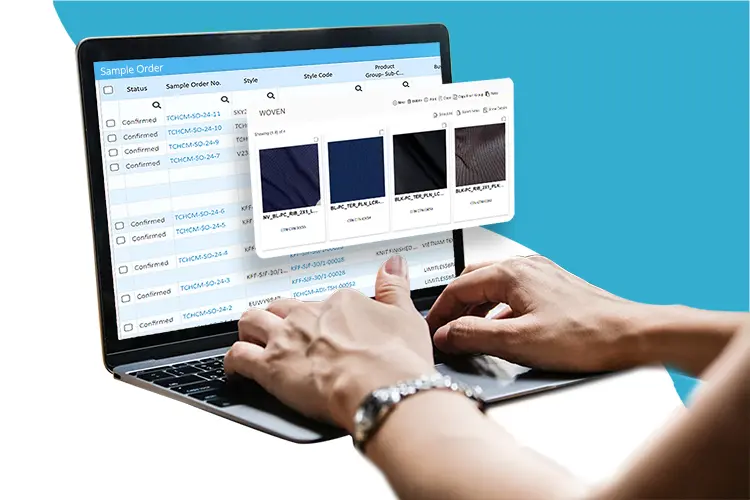

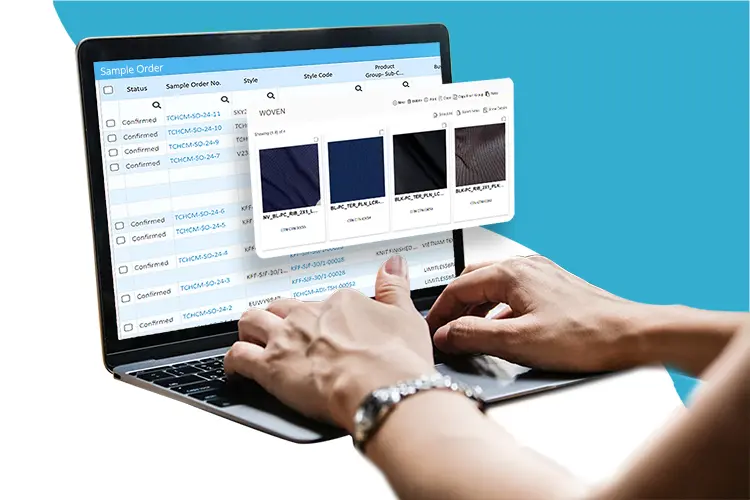

Streamline the fabric sampling process to ensure quality and consistency.

- Define fabric properties precisely on sample orders.

- Manage the fabric development process, detailing required quantities and delivery dates.

- Evaluate samples rigorously for quality assurance.

- Implement a thorough fabric approval process.

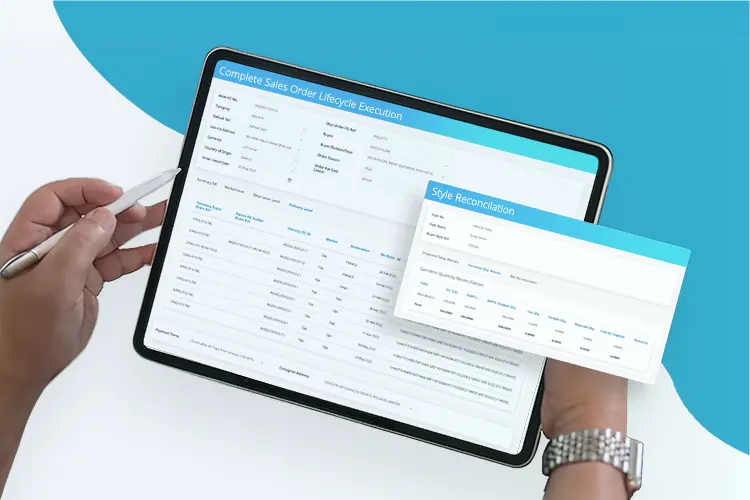

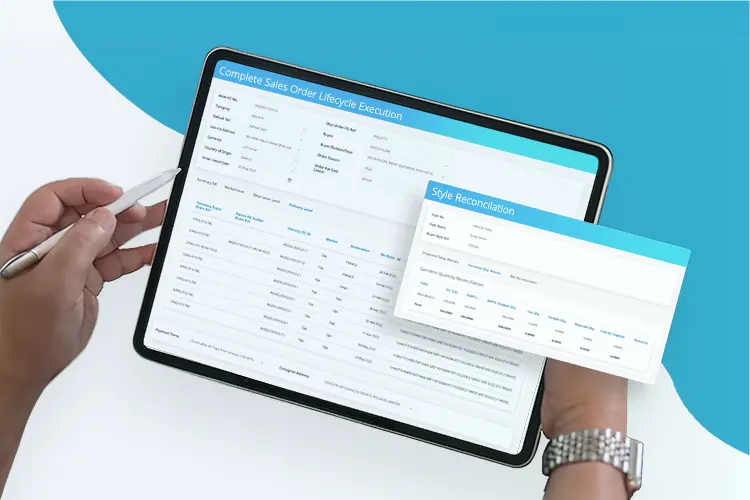

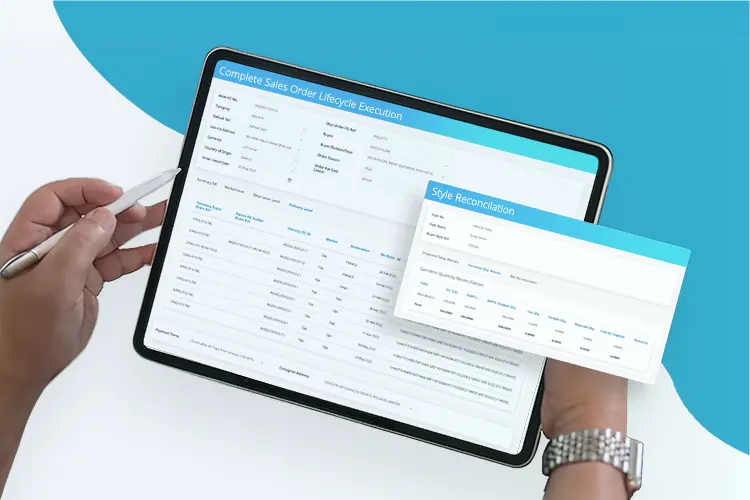

Enhance sales order efficiency and accuracy.

- Use a quick entry screen for fast order processing.

- Automate field population based on buyer and order terms.

- Efficiently manage and split orders as required.

- Oversee the sales order lifecycle, from projections to confirmations and deliveries.

Strategically plan and manage material requirements.

- Consolidate material requirements based on confirmed orders.

- Make informed decisions to procure, produce, or adjust stock levels.

- View material requirements comprehensively, from fiber to finished fabric and garment.

- Automate purchase order generation for efficiency.

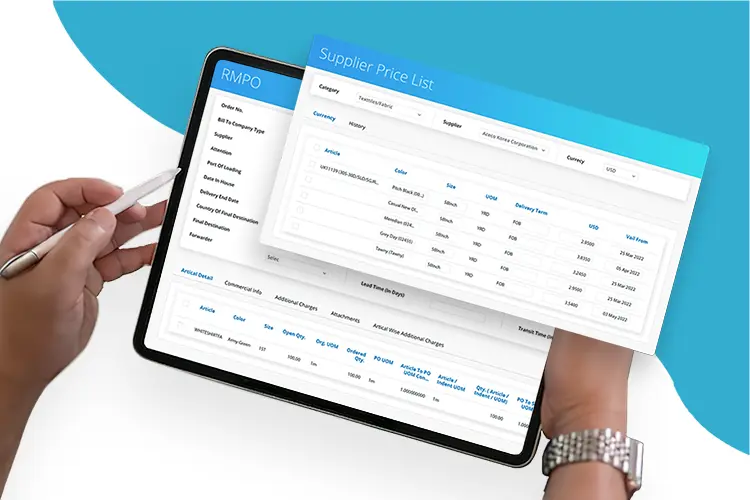

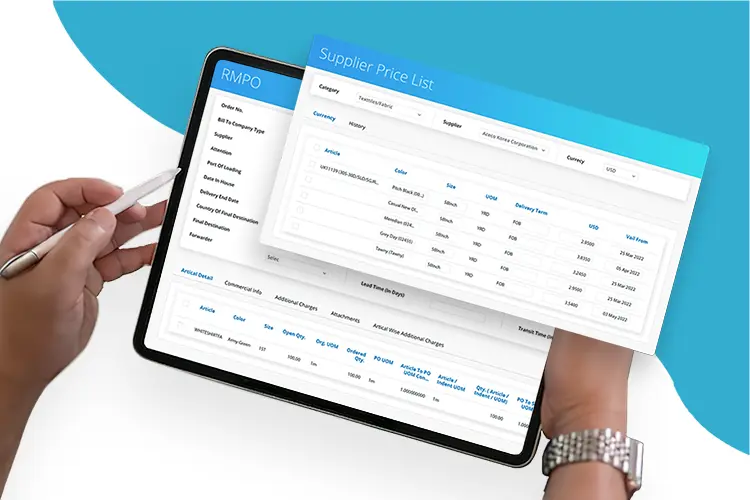

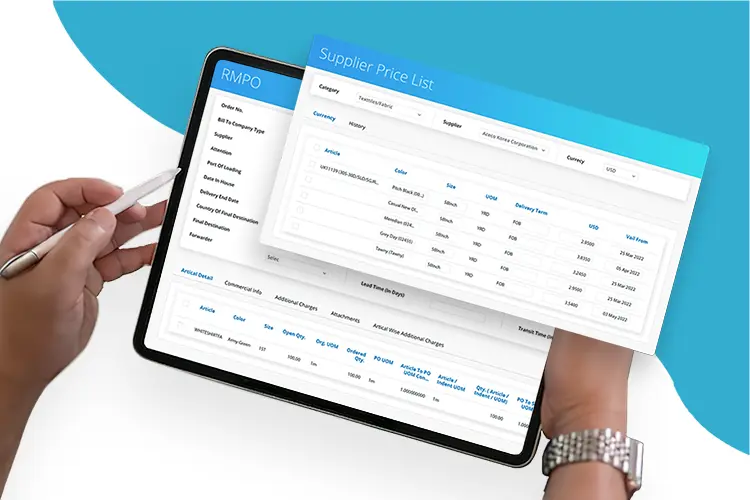

Efficiently manage procurement by keeping track of purchase orders, supplier performance, and inventory levels.

- Streamline procurement processes with an overview of purchase orders, supplier performance, and inventory.

- Employ supplier evaluation mechanisms for optimized supplier management.

- Implement material requirement planning and automatic reordering to ensure supply chain efficiency.

- Manage and fulfil material necessities promptly with advanced procurement tools.

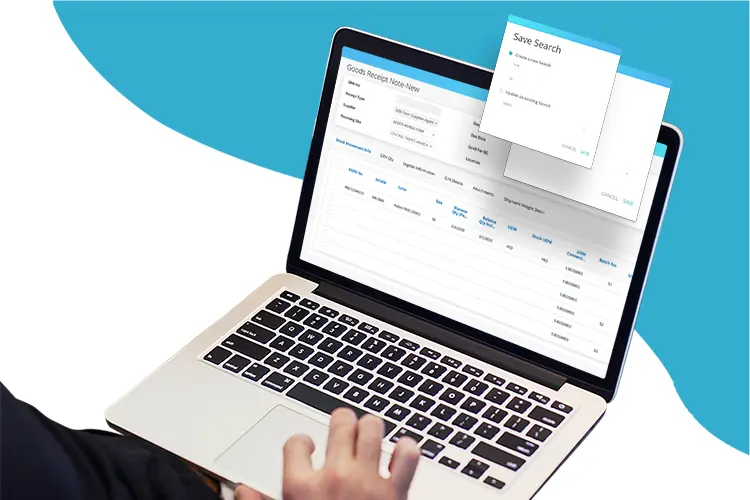

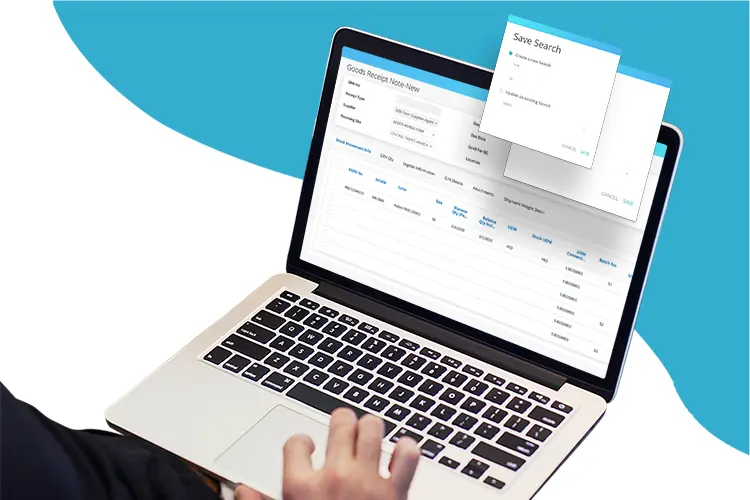

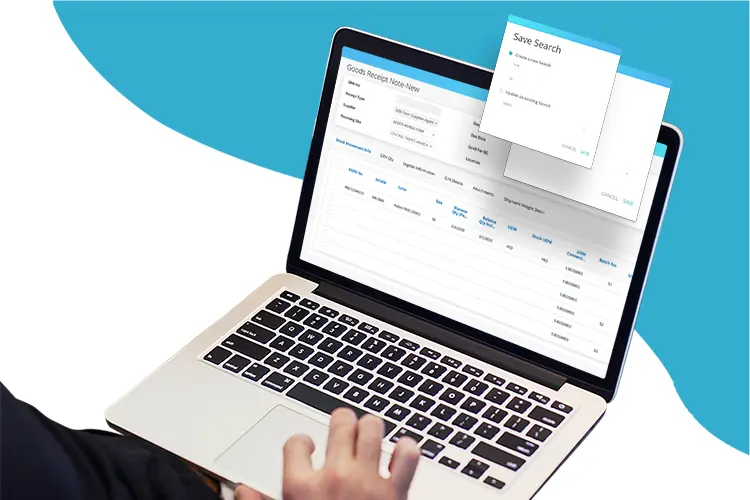

Maintain high standards of inventory management and quality control.

- Implement barcode/QR code-based inventory tracking systems.

- Control inventory at the roll/batch level for precision.

- Accurately categorize material quality and manage inventory accordingly.

- Define detailed specifications for each inventory roll.

- Generate automatic supplier debit notes in cases of quality rejections and shortages.

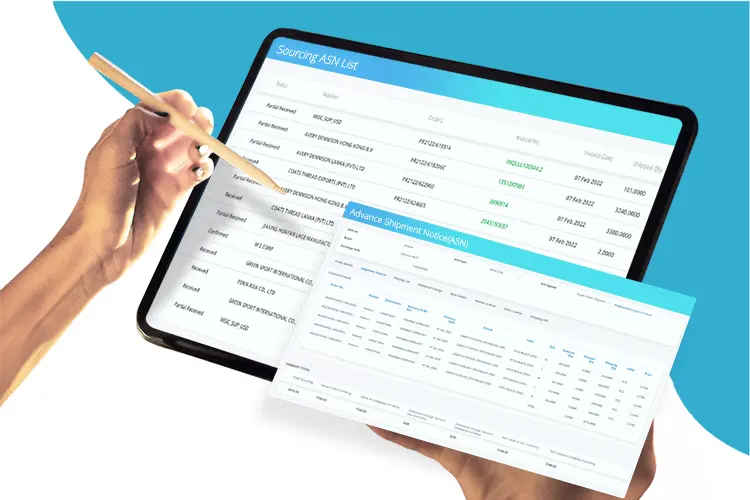

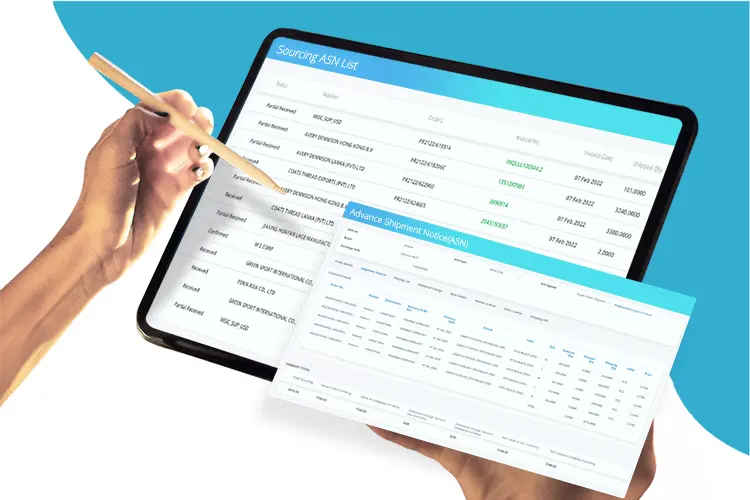

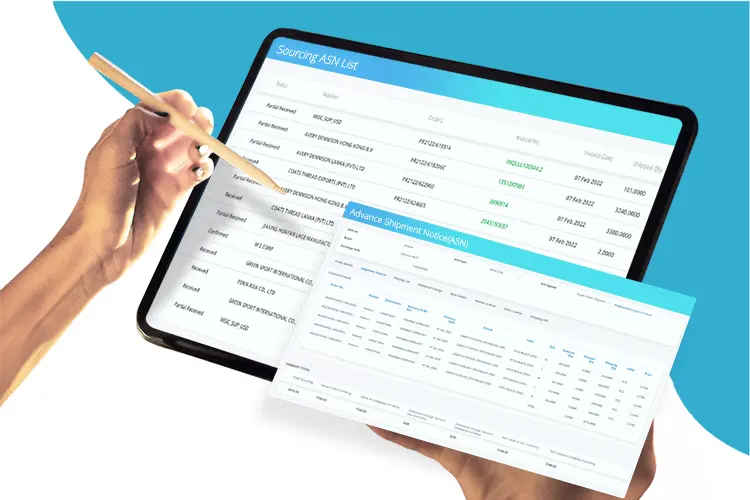

Effectively manage both inbound and outbound shipment processes.

- Coordinate pre-shipment and customs bookings.

- Accurately track inbound and outbound shipment expenses.

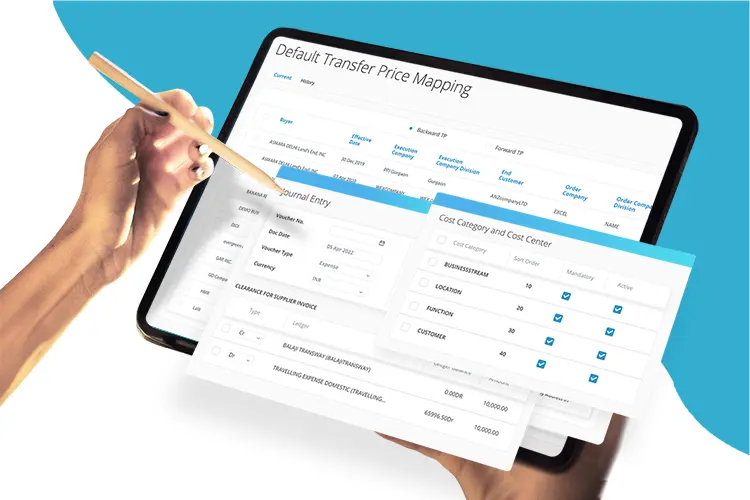

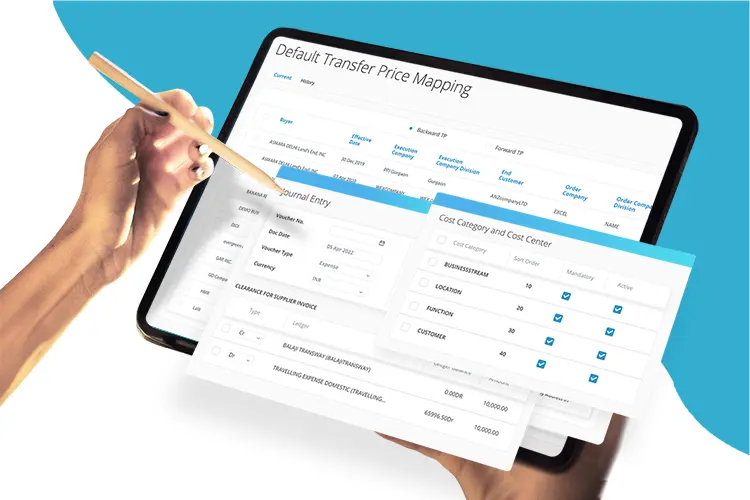

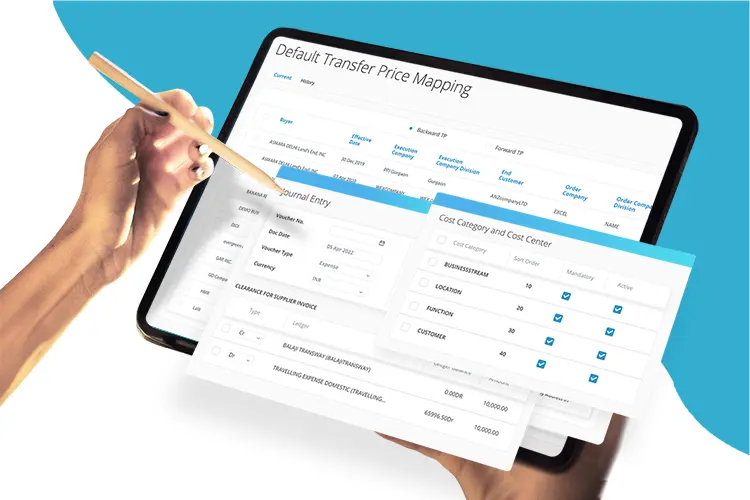

Achieve comprehensive financial oversight and reporting.

- Consolidate financial data for a clear overview of fiscal health.

- Efficiently manage payables and receivables for balanced cash flows.

- Generate detailed financial reports for strategic decision-making.

- Continuously monitor revenue growth and profitability for long-term financial success.

Capture orders, track shipments, and monitor sales performance to forge stronger customer relationships and drive profitability.

- Efficiently capture and manage orders through integrated sales tools.

- Track shipments in real-time for improved customer service and efficiency.

- Monitor and analyze sales performance for revenue optimization.

- Implement measures to prevent stock discrepancies and minimize carrying costs.

- Understand market trends and customer buying patterns to drive sales revenue.

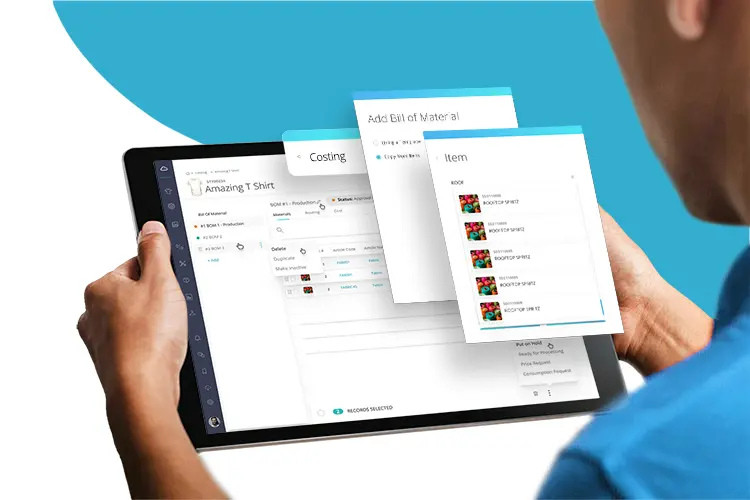

Gauge the financial impact of raw materials, labour, and overheads with precision, ensuring optimal costing for maximized profits.

- Determine accurate, real-time costs of raw materials, labour, and overheads.

- Utilize comprehensive expense tracing and allocation for precise cost management.

- Establish optimal costing parameters for maximized profit margins.

- Understand true production costs for strategic pricing and gaining competitive advantage.

Centralize and manage a robust database of fibres, yarns, and fabrics.

- Create detailed, configurable records for each product type.

- Develop comprehensive Fabric Tech Packs, encompassing product groups, sub-categories, counts, construction, GSM, and various units of measure.

- Streamline and maintain accurate costing for yarns and fabrics.

Efficiently define and manage textile manufacturing operations.

- Detail process operations and sub-operations.

- Calculate production time and cost components for each sub-process.

- Record and analyse process/operation SMV and SMV rates, along with process wastages and operation losses.

- Map specific machines to each sub-process and define operational sequences.

- Develop multiple routing masters, tailoring operation attributes for efficiency, time, productivity, and cost.

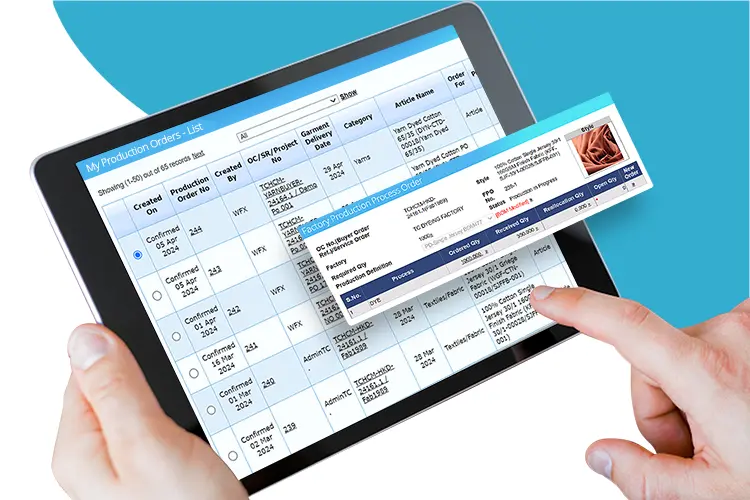

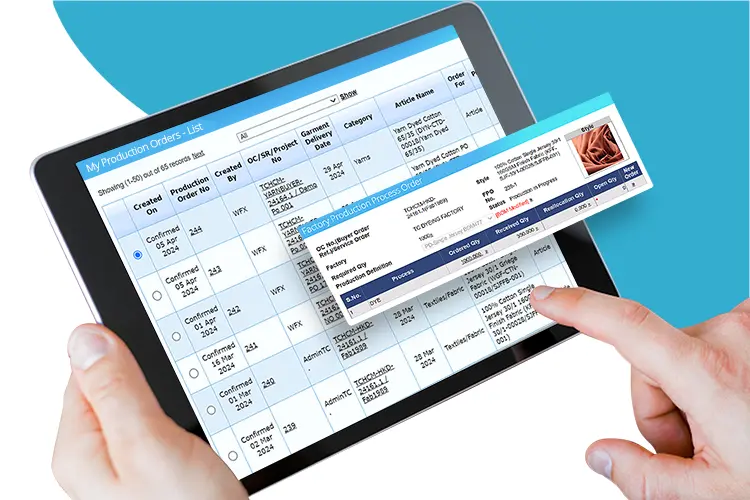

Optimize production workflows and processes.

- Seamlessly create and integrate work orders into production planning.

- Monitor and manage the status of work and quantity orders in real time.

- Schedule factory production orders effectively, attaching relevant production routings.

- Enhance lot/batch traceability with efficient roll selection for LOT number creation.

- Allocate machines strategically for individual and combined job orders.

- Record detailed information on machine output, including shift and operator details.

- Analyze material consumption at each process stage for variance management.

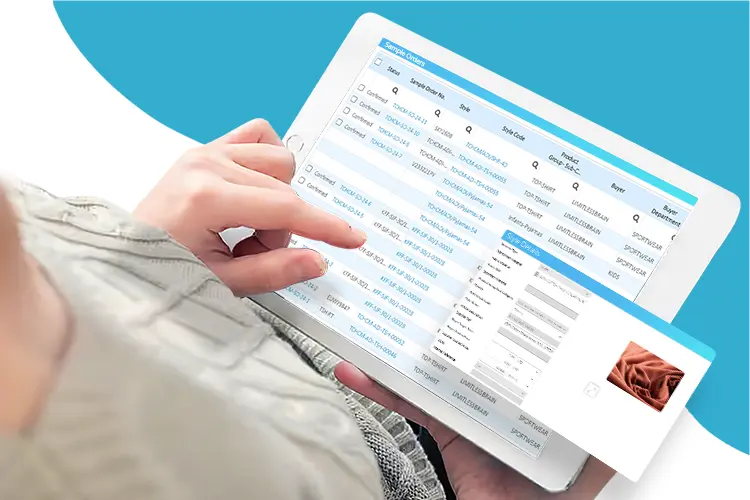

Streamline the fabric sampling process to ensure quality and consistency.

- Define fabric properties precisely on sample orders.

- Manage the fabric development process, detailing required quantities and delivery dates.

- Evaluate samples rigorously for quality assurance.

- Implement a thorough fabric approval process.

Enhance sales order efficiency and accuracy.

- Use a quick entry screen for fast order processing.

- Automate field population based on buyer and order terms.

- Efficiently manage and split orders as required.

- Oversee the sales order lifecycle, from projections to confirmations and deliveries.

Handle recipe details with precision for each colour variant.

- Maintain a detailed recipe master for each colour and optimize lap dip processes for fabric color consistency.

- Register and catalog multiple approved recipe versions for flexibility and accuracy.

- Manage and create lap dip-wise recipes to accurately calculate recipe costs.

- Streamline the approval process based on buyer requirements.

- Manage dyes and chemical consumption calculations.

Strategically plan and manage material requirements.

- Consolidate material requirements based on confirmed orders.

- Make informed decisions to procure, produce, or adjust stock levels.

- View material requirements comprehensively, from fiber to finished fabric and garment.

- Automate purchase order generation for efficiency.

Efficiently manage procurement by keeping track of purchase orders, supplier performance, and inventory levels.

- Streamline procurement processes with an overview of purchase orders, supplier performance, and inventory.

- Employ supplier evaluation mechanisms for optimized supplier management.

- Implement material requirement planning and automatic reordering to ensure supply chain efficiency.

- Manage and fulfil material necessities promptly with advanced procurement tools.

Maintain high standards of inventory management and quality control.

- Implement barcode/QR code-based inventory tracking systems.

- Control inventory at the roll/batch level for precision.

- Accurately categorize material quality and manage inventory accordingly.

- Define detailed specifications for each inventory roll.

- Generate automatic supplier debit notes in cases of quality rejections and shortages.

Effectively manage both inbound and outbound shipment processes.

- Coordinate pre-shipment and customs bookings.

- Accurately track inbound and outbound shipment expenses.

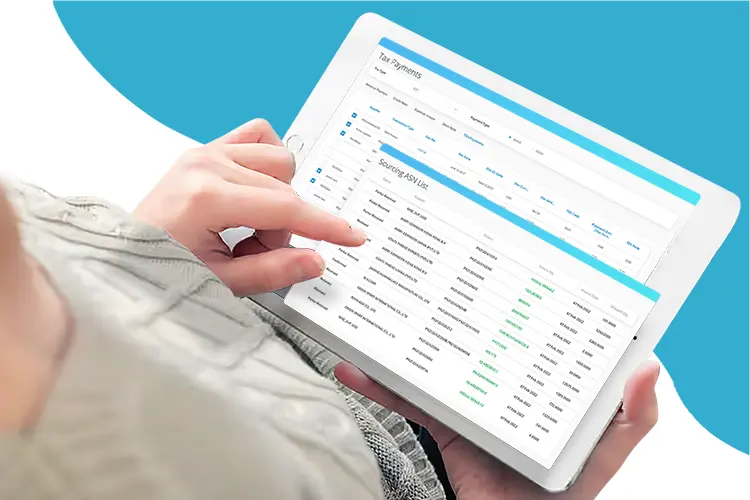

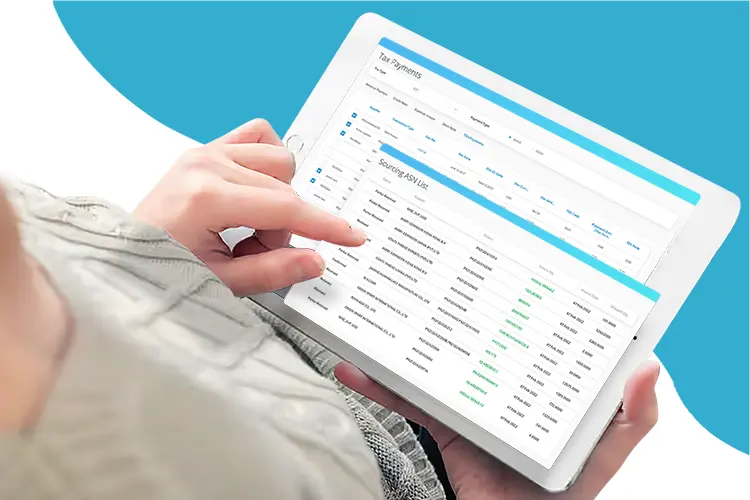

Achieve comprehensive financial oversight and reporting.

- Consolidate financial data for a clear overview of fiscal health.

- Efficiently manage payables and receivables for balanced cash flows.

- Generate detailed financial reports for strategic decision-making.

- Continuously monitor revenue growth and profitability for long-term financial success.

Capture orders, track shipments, and monitor sales performance to forge stronger customer relationships and drive profitability.

- Efficiently capture and manage orders through integrated sales tools.

- Track shipments in real-time for improved customer service and efficiency.

- Monitor and analyze sales performance for revenue optimization.

- Implement measures to prevent stock discrepancies and minimize carrying costs.

- Understand market trends and customer buying patterns to drive sales revenue.

Ride the ‘Weave’ of Success with Textile ERP

WFX Textile ERP offers a plethora of tangible benefits, making it an indispensable tool in the textile industry:

Vertically integrated solution

WFX offers a vertically integrated ERP solution from garment to textile manufacturing for better visibility and efficient decision-making leading to seamless information flow and informed business strategies.

Reporting tools with real-time data

Efficient decision-making processes enabled by a single integrated database for all business processes, leading to seamless information flow and informed business strategies.

Easy access to customer data & faster response times

Increased customer satisfaction and retention, and growth in sales due to improved on-time delivery and order accuracy.

Better inventory planning & procurement management

Reduction in operational costs, increase in efficiency, which leads to improved profit margins and competitive advantage.

Dedicated security resources & encrypted data

Protection against potential data breaches, assuring business continuity and reinforcing customer and stakeholder trust.

Automation of manual tasks & implementation of smarter workflows

Greater internal efficiency, saved time, and increased productivity leading to profitability and business growth.

Effective demand forecasting, lean inventory & transparency in business

Mitigation of production bottlenecks, enhancement of efficiency across operations, ultimately improving reliability, credibility, and profitability of the business.

Intuitive navigation and a user-friendly interface

Users can dive right in without extensive training, saving time and improving productivity while still enjoying a powerful user experience.

Adjust and tailor the platform to align to your processes

Each client gets a personalized solution that matches their unique efficiency needs ensuring maximum ROI from the textile industry software implementation.

Frequently Asked Questions (FAQs)

Don't find an answer to your question here? Contact us directly

WFX ERP stands out as an ERP for textile and manufacturing industry. It’s tailored to industry-specific needs with modules like Production Management, Lab Dips, Recipe Management, Fabric Sampling, and more, streamlining textile business operations.

We offer comprehensive support during and after implementation with our ERP for textile industry. This includes assistance with system setup, data migration, user training, and ongoing technical support. Customer support teams are available 24/7 to help you resolve any technically issues promptly.

Yes, WFX’s textile manufacturing software is designed to help you manage operations in multiple business locations, languages, units of measurements, tax situations, and support transactions in multiple currencies.

Our ERP software for the textile industry is a 100% cloud-based solution that you can access right from your browser. It gives you flexibility, anywhere access, and eliminates maintenance costs.

WFX's textile manufacturing ERP software is a highly scalable solution, designed to adapt to your business's growth and evolving requirements. As your company expands, the system can seamlessly accommodate additional users, departments, and functionalities.

Yes, we have designed an advanced traceability and sustainability solution designed to help all fashion businesses visualize their global supply chain, manage certifications, audit statuses and communicate compliance with buyers. The solution integrates seamlessly with our ERP for textile and apparel industry—giving you access to accurate reporting and complete visibility.

Yes, WFX Textile ERP is designed to help you manage operations in multiple business locations, languages, units of measurements, tax situations, and support transactions in multiple currencies.

By Team WFX

By Team WFX

By Vishakha Somani

By Vishakha Somani