Garment Costing: How costs are calculated in the fashion industry

-

Introduction

When it comes to the costing of garments (or any fashion product for that matter), there can be several obvious and some not so obvious pricing elements. That is what makes costing in the garment industry one of the most complex operations for any business.

Generally, costing means assigning value to all resources used in the production of goods and services, including raw material, labor and even shipping or marketing costs. In costing for garment manufacturing, we typically combine all expenses incurred in the making of a garment—including direct labor costs, material costs, conversion costs and overhead costs.

In this article, we will not just discuss the definition and components of apparel costing but also explain the various costing stages in the fashion industry, and how you can use modern digital data systems to manage your production costs.

-

What is ‘manufacturing cost’?

According to the American Accounting Association, cost is defined “the foregoing, in monetary terms, incurred or potentially to be incurred in the realization of the objective of management, which may be manufacturing of a product or rendering of a service.”

The less word definition of manufacturing cost is that it’s the total expenditure incurred to produce a product or service. It is also called conversion cost, production cost and direct material cost. The total cost would include the costs of raw materials, labor, and other expenses like utilities, rent etc.

For a business, there are typically two types of costs, direct and indirect.

- Direct Costs are expenses on actual costs incurred during the production of goods or services (i.e., labor, materials).

- Indirect Costs are the general expenses that keep a business running but cannot be directly attributed to the production of a product (i.e., rent, utilities).

Understanding these costs is vital for accurately pricing garments. Misestimating either direct or indirect costs can lead to significant financial miscalculations, affecting profitability.

-

The importance of apparel costing

Cost management is crucial for understanding how expenses impact profitability. Monitoring every cost and expense closely prevents unnecessary wastage of finite resources and ensures the business remains profitable.

Costing in apparel industry helps manufacturing companies determine the cost-per-unit of producing a garment. This tool provides an accurate analysis of costs and helps ascertain the profitability of each product. It guides businesses in setting prices for their goods.

Key Objectives of Apparel Costing

- Classification and Budget Allocation: Costing helps classify and subdivide costs, allowing businesses to allocate budgets effectively for every operation. This sets the stage for measuring efficiencies and implementing budgetary control.

- Resource Optimization: By highlighting where resources are being wasted or underutilized, costing enables businesses to make better use of limited resources, keeping overall costs down and profits high.

- Management Control: Apparel costing is a vital management tool. It aids in cost audits, price determination, and better decision-making by accurately predicting production costs. This leads to improved profitability and increased customer satisfaction.

- Cost Reduction and Optimization: Costing helps identify areas where expenses can be reduced. For example, substituting expensive imported raw materials with more affordable alternatives that offer similar results can lower production costs.

- Strategic Planning: The costing process assists management in developing effective expansion strategies. It helps manage seasonal variations in volume and costs, ensuring stability and growth.

- Performance Insights: Beyond identifying problems, costing reveals what’s working well in the business. This insight is invaluable for formulating and implementing incentive and bonus plans.

In essence, a robust apparel costing strategy is the foundation of any successful business. It not only ensures efficient resource management but also drives healthy profitability and strategic growth.

-

Stages Of Garment Costing

Product costing in fashion manufacturing involves four main stages: preliminary costing, cost of adoption, pre-production costing, and actual cost analysis. Each stage plays a vital role in ensuring the financial viability of a design from conception to final production.

- Preliminary or Pre-Costing Stage: This stage involves making initial cost estimates before samples are created. This stage provides a rough idea of the potential costs based on similar styles, allowing designers to gauge the feasibility of their concepts. If a design appears too costly, it can be modified or eliminated early in the process, saving time and resources.

- Cost of Adoption: The cost of adoption breaks down the expected investment required for the design, including materials, labor, and overhead. This stage involves a detailed analysis of each component of the garment, determining how to assemble them efficiently to meet a specific price point. The assessment relies on samples and available data to ensure the design can be produced cost-effectively.

- Pre-Production Costing: This covers all fixed expenses estimated to be incurred before actual production begins. This includes costs related to pattern making, sample development, and initial fabric purchases. Pre-production costing ensures that all necessary resources are allocated correctly and that any potential financial risks are identified and mitigated before mass production starts.

- Actual Cost Analysis: This involves comparing the original estimates of materials and labor costs to the allowed budget for the project. This stage provides an accurate estimation of the product’s price at different production stages and tracks expenditures in real-time. By continuously monitoring costs, businesses can ensure they stay within budget and adjust as needed to maintain profitability.

These are some of the most common costing stages in the apparel supply chain, but it goes without saying that each business may have its own unique version of implementing these strategies.

-

Cost Components in Garment Manufacturing

A product merchandiser typically handles the cost of a garment. They must consider various factors, including the cost of raw materials, operating expenses, competition, desired profit margins as well as buyer expectations. Central to this process is the Bill of Materials (BOM), which details all components required to manufacture a garment, providing a comprehensive overview of all costs involved.

Key Components of Manufacturing Cost

- Fabric: This is usually the most significant component, accounting for 60-70% of the cost of a basic style garment. The type and quality of fabric often plays a crucial role in determining the overall production cost.

- Trims: Trims include all materials other than fabric used to complete a garment, such as threads, buttons, zippers, elastic, rivets, lace, labels, and other accessories. The cost, quantity, and labor required to apply trims contribute to the total cost of the garment.

- Cut, Make & Trim Charges (CMT): Also known as CMTP (cut-make-trim-pack) costs, these are the ‘cost of making’ charges. CMT is calculated by multiplying the total cost per hour by the total number of hours it takes to make the style, divided by the number of units produced. The contractor’s profit is also included in this cost.

- Value Addition: Special processes such as printing, embroidery, washing, or appliqué fall under ‘value-added services.’ Each of these processes has its own subset of costs that can significantly impact the overall garment cost.

- Garment Testing: Inspection and testing occur at various stages of garment manufacturing—raw material, partially finished, assembled, and post-finishing. These tests include chemical tests, appearance after storage tests, dimensional stability tests, and color fastness tests.

- Quality Control: QC-related costs are divided into four main categories: appraisal costs, preventive costs, and internal and external failure costs. These costs are incurred to identify and prevent defects during product development and production.

- Labels and Packaging: These costs depend on the size, thickness, printing mechanism, and material chosen. The number of labels per item also plays a significant role and must be considered.

- Transportation and Logistic Costs: These expenses cover the movement of products from the factory to the store or warehouse, including freight and shipping costs. These costs can vary widely depending on the sourcing location.

- Overhead Costs: While calculating manufacturing overheads, you can include rent, electricity bills, equipment repairs, and indirect labor costs that are not directly linked to any specific product or service.

- Profit: This ‘cost’ represents the earnings the business makes from selling the produced goods. It is the final component that ensures the sustainability and growth of the business.

-

Garment Costing Methods & Techniques

Understanding different garment costing methods and techniques is essential for accurately calculating the cost of production and ensuring profitability. Here are some of the key techniques used in the fashion industry:

- Direct Costing: Direct costing, also known as variable costing, involves calculating only the variable costs directly associated with the production of garments. This method focuses on the costs that vary with the level of output, such as raw materials and direct labor.

Advantages: Simplifies cost calculation by focusing only on variable costs. It also provides a clear picture of the contribution margin, helping in decision-making.

Disadvantages: Ignores fixed costs, which can lead to an incomplete understanding of total expenses. Is is not suitable for long-term financial planning as it overlooks overheads.

- Absorption Costing: Absorption costing, or full costing, includes all costs associated with manufacturing a product, both fixed and variable. This method allocates a portion of fixed overhead costs to each unit produced, ensuring that all costs are accounted for.

Advantages: Provides a comprehensive view of total production costs. Useful for long-term pricing and profitability analysis.

Disadvantages: It is more complex to calculate due to the inclusion of fixed costs. It can sometimes distort cost per unit if production levels fluctuate.

- Variable Costing: Variable costing, like direct costing, focuses only on variable costs. However, this method is used primarily for internal decision-making and management control rather than external financial reporting.

Advantages: Helps in understanding the impact of variable costs on profitability, and aids in short-term decision-making and cost control.

Disadvantages: Excludes fixed costs, which can lead to an incomplete cost structure. Not accepted under generally accepted accounting principles (GAAP) for external reporting.

- Activity-Based Costing (ABC): Activity-based costing assigns costs to products based on the activities required to produce them. This method identifies all activities in the production process and assigns costs based on the resources each activity consumes.

Advantages: Provides a more accurate cost per product by identifying specific cost drivers. It helps in identifying inefficiencies and areas for cost reduction.

Disadvantages: Can be time-consuming and complex to implement. Also, it requires detailed data collection and analysis.

- Standard Cost Accounting: Standard cost accounting involves using pre-determined costs for materials, labor, and overhead to calculate the cost of production. These standards are based on historical data and industry benchmarks.

Advantages: Simplifies budgeting and cost control by providing benchmarks. It facilitates variance analysis by comparing actual costs to standard costs.

Disadvantages: May not reflect current market conditions or changes in production processes. It requires regular updates to ensure accuracy.

Selecting the appropriate costing method will depend on various factors, including the nature of your business, the complexity of production processes, and your specific financial goals—all of which will affect the total manufacturing cost calculation.

- Direct Costing: Direct costing, also known as variable costing, involves calculating only the variable costs directly associated with the production of garments. This method focuses on the costs that vary with the level of output, such as raw materials and direct labor.

-

What is a Fashion Cost Sheet? How You Can Make a Cost Sheet

A garment or apparel cost sheet is a comprehensive statement that details the various components (as discussed above) constituting the total cost of producing a particular product. Cost sheets for manufacturing company can be prepared using both historical data and estimated costs based on a set garment costing formula.

Creating a Sample Fashion Cost Sheet

To create a sample fashion cost sheet, you’ll need the following information:

- Materials Consumed

- Direct Labor/Wages

- Direct Expenses

- Prime Cost – (1 + 2 + 3)

- Factory Overhead

- Work/Factory Cost – (4 + 5)

- Office/Administrative Overheads

- Total Cost of Production – (6 + 7)

- Cost of Goods Sold

- Selling and Distribution Overheads

- Total Cost aka Cost of Sales – (9 + 10)

- Profit

- Sales – (11 + 12)

You can copy the above tabulation and just fill in relevant values against each category to create your own free Apparel Cost Sheet template.

-

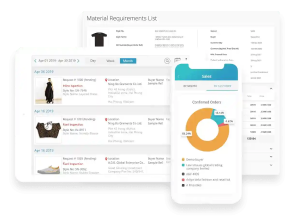

Using WFX Fashion ERP To Reduce Fashion Manufacturing Costs

WFX ERP is a cloud-based enterprise resource planning solution designed to help fashion companies reduce costs and boost productivity. Trusted by industry leaders like InQube, Indochine, Phong Phu, and Asmara, WFX ERP offers several cost-saving benefits.

Ways WFX ERP Minimizes Costs

- Reduce Inventory Costs: Optimizes inventory levels at each point in the supply chain, preventing overstocking and understocking. For example, Phong Phu used WFX ERP to streamline their inventory management, significantly reducing excess stock and associated costs.

- Reduce Labor Costs: Automates manual tasks, freeing employees to focus on higher-value activities. Indochine leveraged WFX’s apparel software to automate repetitive data entry, resulting in substantial labor cost savings.

- Boost Productivity: Improves accessibility to essential information. Employees at Asmara can quickly retrieve customer details and other data without delays, enhancing their efficiency and productivity.

- Reduce Material Costs: Ensures managers can maximize resource utilization. EAM Maliban Textiles used WFX to eliminate low-value manual operations, freeing up time for material management and reducing material costs by 5%.

- Reduce Sampling Costs: Uses analytics to monitor and analyze product performance. Song Hong reduced sampling costs by tracking every sample iteration developed for each buyer using WFX’s Sample Feedback and Approvals tool, improving their sample hit rate.

To learn more about WFX’s apparel management software, contact us today.

-

Conclusion

Understanding and managing fashion manufacturing costs is crucial for profitability. Whether it’s optimizing inventory, automating tasks, boosting productivity, reducing material costs, or cutting sampling expenses, ERP software for apparel industry, such as WFX, can provide tangible benefits to your business.

If you’re looking to manage your fashion business more effectively, consider exploring our 100% cloud-based, modern, state-of-the-art Apparel ERP or Fashion PLM solutions. Designed for fashion, footwear, and home furnishing manufacturers and brands, these tools help control inventory and ensure you never miss an opportunity.