How digital Tech Packs can prevent costly manufacturing errors

-

Introduction

The tech pack (or technical package) is the foremost foundational steps in the development of any product. It is an in-depth document that provides a detailed visual and technical representation of a product’s design.

In fashion, you can think of it as an instruction manual for a garment, detailing all its components with specifications about measurements, colorways, construction instructions, and so on. It’s indispensable communication tool between designers and manufacturers, written in a common language.

The fashion tech pack needs to be created even before you can go looking for manufacturers to produce your collection. It defines your requirements to be communicated them clearly to your manufacturing partner.

Once finalized, the tech pack is also the ledger for any iterations or moderations made during production. It also helps keep track of each sample before you can get to the finished product. Once all this information has been recorded and agreed upon, the tech pack becomes a written set of instructions that garment suppliers must follow to bring your product visions to life.

To learn more about how to create a fashion tech pack, read our ultimate guide for clothing tech packs!

A comprehensive tech pack allows manufacturers to execute patterns and samples better. It ensures that everyone involved in the product development process has a clear understanding of what needs to be done—and how—to avoid costly manufacturing errors.

-

How Can Tech Packs Save Your Brand Time & Money?

Without a well-made tech pack, your manufacturers can make errors that can lead to costly rework. Here are 6 ways tech packs can help you avoid those mistakes:

1. Tech packs can help reduce communication-related problems

The first benefit of a tech pack is that it can help you to avoid any kind of communication-related problems. As mentioned, a tech pack is written documentation. It contains all the information about your design, pattern, sample and measurements.

A tech pack provides complete clarity of design intent. This means that everyone involved in the research and development process will know exactly what you want to create. They won’t need to make assumptions based on their own experience or understanding.

So, using a tech pack ensures that there is no room for error or confusion when you are developing your product with the factory or supplier. Everyone has access to the same information (including Adobe Illustrator files) and everything is clear from the beginning so there is less risk of miscommunication and misunderstanding.

2. Tech packs take care of time zone troubles

As a fashion brand, your goal is to produce high-quality products and ship them quickly. Time zone differences can create problems that may lead to delays while you or your apparel manufacturer wait to get back in touch. With digital tech packs, this is less likely to happen because a tech pack is an easy reference point that can be accessed 24/7.

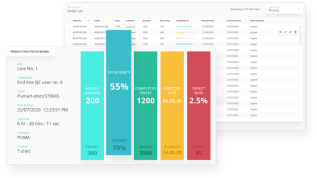

In addition, with tech pack tools you can make any adjustments by updating the tech pack in real-time so that everyone has access to the most current version. This is not possible with tech packs made in Microsoft Excel which is why we recommend a digital tech packing tool such as WFX PLM.

3. Tech packs help manufacturers set and stay on budget

Product costing errors generally occur when brands and manufacturers don’t communicate their expectations clearly or when quality control is not handled properly. Tech packs are the antidote to this problem.

One of the main reasons for product costing errors is a lack of clarity regarding the Bill of Materials (BOM). If your tech pack does not include a comprehensive list of materials needed, with exact quantities and measurements, you can expect your manufacturer to make their own judgment. This may not align with your vision and certainly not your budget. Your tech pack should mention all required trims, materials and construction requirements so that pricing can be done correctly.

4. Tech packs help manufacturers to allocate resources more effectively

Reducing the number of rounds of prototypes is a key benefit for manufacturers. Once you have a finalized and approved tech pack, the manufacturer can move from prototyping to production without wasting time on corrections or alterations.

In fact, tech packs allow them to allocate manpower and equipment more effectively—a clear set of instructions for each item’s construction enables them to decide whether certain value-additions need to be outsourced and estimate the resources required in-house. A clear tech pack will also ensure that all finished products meet your standards. This can help you avoid errors such as mistakes in stitching, wrong material specifications, incorrect embellishments and so on.

5. Tech packs make it easier to create a Time & Action calendar

In case you’re not familiar with the concept, a Time & Action calendar is used to schedule and monitor all the activities involved in the production and delivery of a product. The T&A gives you an overview of the whole production process, from sampling to delivery.

In the clothing industry, a tech pack is essential in helping you create this calendar by providing you with all the required information, which includes:

- Digitized sketches and illustrations

- The complete specifications of your product

- Measurement details for each part or item on your garment

- Style number, color and material specification for each style

- Bill of Materials (BOM) for each style

6. Tech packs help reduce lead times

A tech pack streamlines the steps of the design process, allowing your team to be able to move quicker from one step to another. This is crucial for reducing lead times as well. Without a tech pack, you have to rely on constant communication with your factory in order for them to re-create your designs or understand your ideas.

With tech packs, communication between you and the factory is simplified because all necessary information is gathered (and recorded) in one document. This process can be further improved by using a digital tech pack tool like PLM/ERP where the design and factory teams can collaborate on a single platform and get real-time updates to get the job done. This allows manufacturers, designers, and brands to work together efficiently—helping companies get their products out faster without unnecessary delays.

-

Conclusion

We can all agree that manufacturing errors are costly and need to be avoided whenever possible. Fashion business tools such as digital tech pack software can help minimize the risk of these mistakes being made. Now that you’re aware of the importance of tech packs, and why you need them—check out some of the best practices and tips for creating a successful fashion tech pack.

If you want to make sure that product quality doesn’t suffer as a result of miscommunication or inaccuracies, investing time in tech packs could be a solid decision. After all, it’s better to spend a little upfront than risk throwing away hundreds if not thousands of dollars on faulty products.