The apparel industry is undergoing multiple simultaneous disruptions, and they’re accelerating:

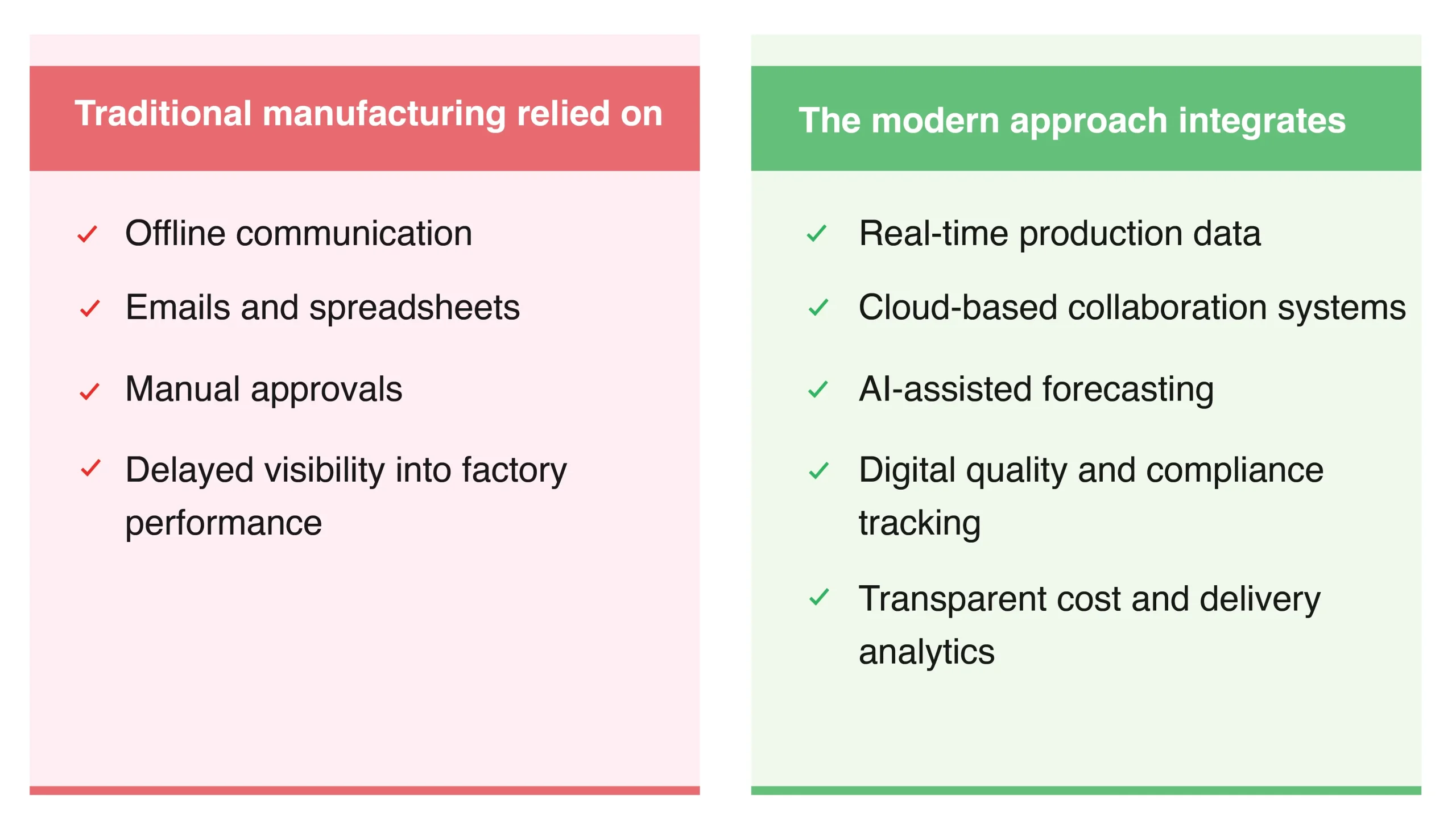

1. Digital Tools Are Becoming Standard, Not Optional

Digital is not a test balloon anymore. AI-enabled design, virtual prototyping, and predictive planning are going from pilot programs to the production floor.

For example, AI design tools can create hundreds of iterations of a garment and give them a digital stamp of approval before they are sewn with a single stitch. This cuts waste, accelerates approvals, and fosters creativity – without skimping on quality.

More and more custom clothing services require a commitment to sustainability and visibility. This flexibility is provided by digital systems that offer traceability from raw material through to the final product.

2. Consumers Want Purpose More Than “Premium”

By 2026, the idea of “premium” will have become much more meaningful. It’s not enough simply to have a brand label; people want to know why you do, what you do. Rather than just probing what a product is composed of, consumers now care about intent and purpose. They are looking to determine why it was made and how it found its way onto the shelf and into their hands.

And this shift has elevated slow fashion from a niche movement to the mainstream. With the environmental toll of fast fashion – from high carbon emissions to massive textile waste generated by unwanted clothing – growing every day, consumers are now moving towards timeless numbers that can last a lifetime. Because, people are tired of wearing clothes that get tossed out after a few months and instead want garments that last longer, feel better, and convey honest information about where they came from.

At last, sustainability is no longer a “nice-to-have.” It’s a deciding factor for many would-be buyers. The proof is in the numbers, with 70% of consumers now willing to spend more on sustainability than they were previously, and younger generations, especially 73% Gen Z (Source: First Insight & Wharton Report 2024), are even willing to pay more for brands that are genuinely transparent and responsible.

In short, fashion buyers are becoming more thoughtful. They’re not chasing trends as much as they’re choosing values. Therefore, it is clearly visible now, brands that align with this mindset are earning stronger trust and long-term loyalty.

3. Materials Matter More

Organic cotton was at the center of sustainability conversations in 2024. By 2026, the goal has changed to advanced but agricultural by-products, such as mycelium leather or Tencel Lyocell textiles. In fact, the agricultural waste market is reportedly set to grow from $12 million in 2024 to an estimated $336 million by 2033. The rapid development in the market for bio-fabricated materials indicates that material innovation will lead the future of sustainable fashion.

Above all, for fashion brands, this means the future of materials won’t be limited to what’s familiar. It will be shaped by what’s smarter, more regenerative, and built for long-term impact.

4. Advanced AI & Predictive Production

AI has evolved the core fashion market. A new wave of AI-based technology is transforming the way clothes are made and sold. Instead of tracking trends after they happen, now designers and makers employ AI to forecast trendlines and customer preferences. This mitigates inventory risk and bad decisions.

To sum up, from forecasting demand to optimizing cutting paths and scheduling factory sequences, AI is now embedded in operations, not just marketing.

5. Radical Traceability and Transparency

Brand claims are no longer enough for consumers and regulators alike; they want proof.

Blockchain, RFID, and traceability systems can now:

- Track materials from the source

- Validate labor and sustainability claims

- Provide real-time supply chain data to buyers.

This trend isn’t marketing, it’s compliance.

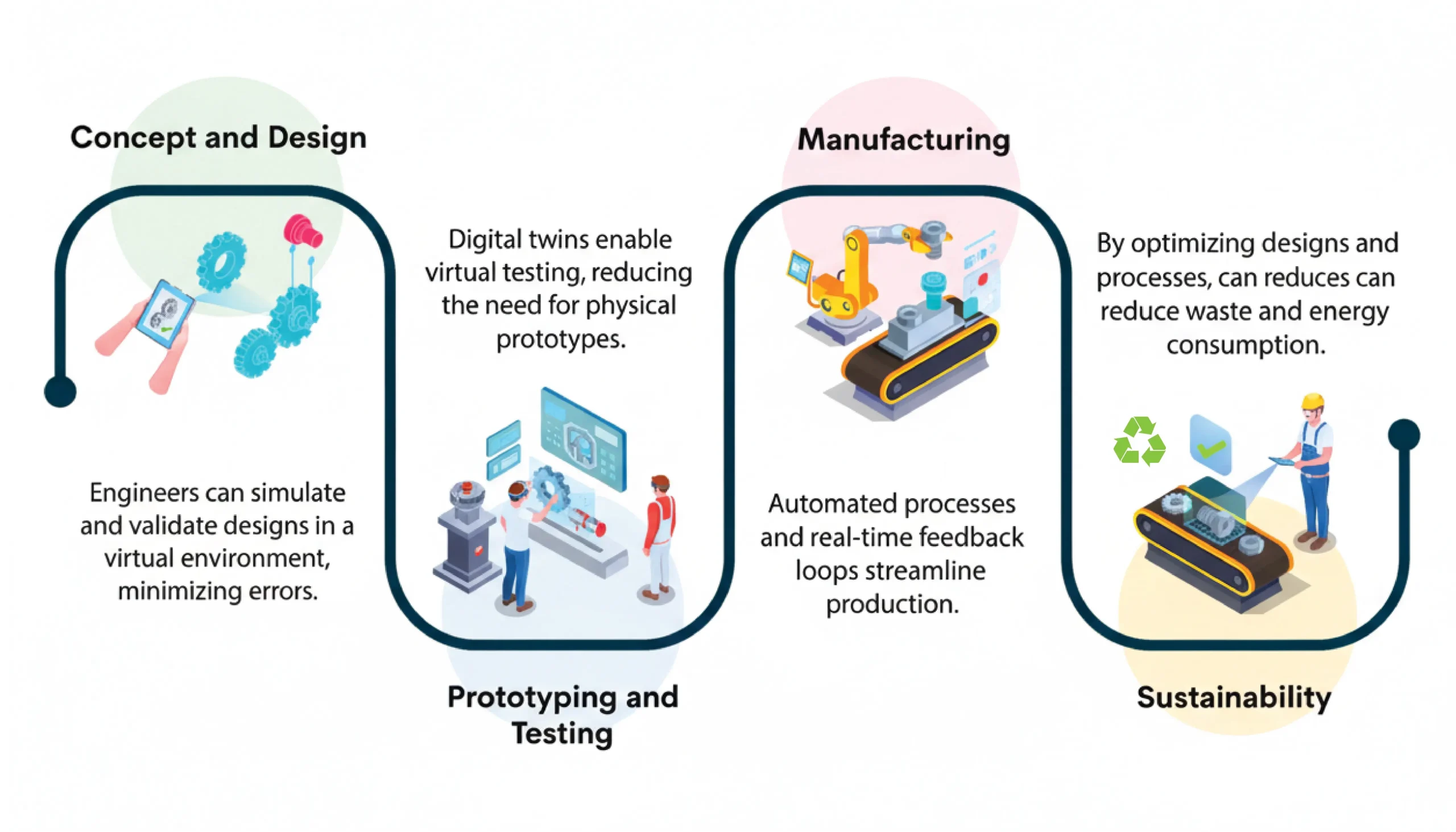

6. Virtual Production & Digital Twins

‘Cluster maps’, or ‘Digital twins’, are digital replicas of physical products and processes. In addition, it provides custom apparel designers and developers the means to visualize how garments fit, move, or behave on the production line.

This reduces waste and increases first-time quality, delivering a large advancement over traditional trial-and-error sampling cycles.

7. Fashion on Demand and Customization

People really like things that are one of a kind. So brands are starting to make things when someone orders them. This means that manufacturers are only making what people need. They are also making each thing special for the person who ordered it. On-demand manufacturing is a way of doing things. It does not waste anything. That’s why many brands are focusing on-demand manufacturing to gain access to a modern audience.

This trend is even more pronounced in the nearshoring, modular factories and microfactories that bring local production models with extremely low lead times and reduced carbon footprint.

8. Sustainability, reducing product wastage, and faster Product Development

Between 2026 and 2030, sustainability in fashion manufacturing will be less about how products are marketed than about how they are made. Among the most significant shifts is the reliance on 3-D modeling and digital prototyping early in the design process.

Rather than creating several physical samples, teams now use 3D prototypes to assess fit, construction, and fabric behavior before any cutting. This minimizes product material waste, speeds approvals, fasters product management, and prevents costly last-minute revisions. The less work that needs to be redone, the less fabric wasted and the fewer resources squandered.

At the same time, higher demand is forcing brands to act faster. Digital product development tools also enable collections to be finalized earlier, allowing manufacturers to identify trends and respond without overproducing. Faster development isn’t about taking shortcuts – though those certainly play a role in the old way of working – it’s about employing data, 3D workflows, and more thoughtful planning to make only what the market is ready for.

The faster a brand can get there while advancing and maintaining its integrity, the more likely it is to succeed sustainably and meet consumers’ emerging demands.