1. Central data location

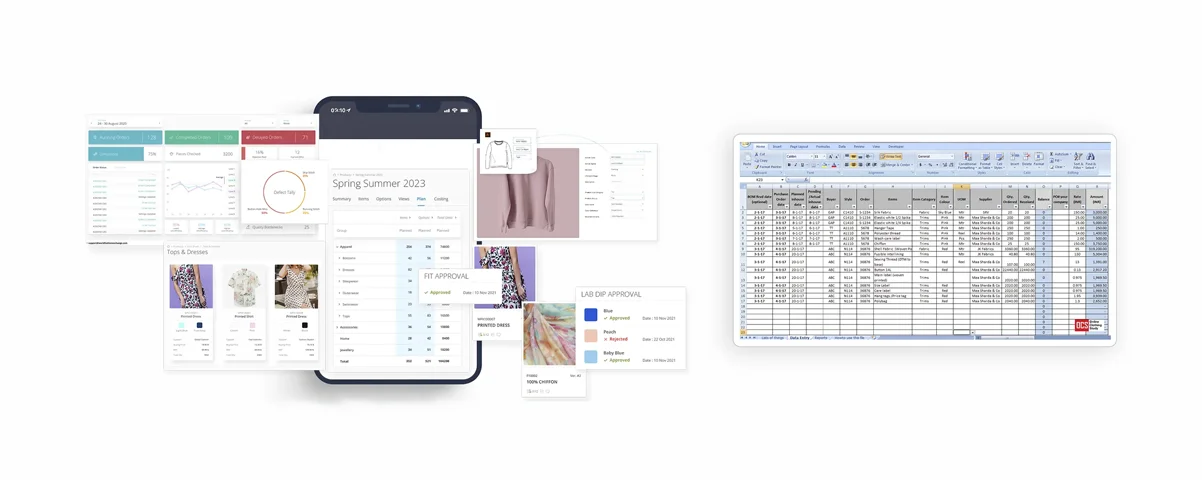

When you build your tech pack in a PLM software, you can access it anywhere, anytime. Everything from your product information, measurement charts to sample iterations, revisions and approval logs are located on a centralized cloud-based platform.

You don’t need to pass around a file to collaborate with your team as everyone can access the file in real-time. Secure storage on the cloud means that you don’t ever have to worry about losing a file.

2. No version confusion

When using excel sheets, every update leads to the creation of multiple versions of a tech pack. And then you have to email it back and forth for reviews and comments to send the updated file to your manufacturer. This makes it impossible to find which version is the latest one.

On the other hand, when you use a PLM system like WFX PLM, you can make edits directly on the platform and your supplier will see them immediately. This saves a lot of time and avoids confusion by keeping everything in one place. No more wondering if all departments are working off the latest version of a technical spec sheet with PLM.

3. Faster to create, easier to understand

With WFX PLM, there’s no need to search for new tech pack templates every time you need to create a new product. In PLM, there are varieties of tech pack templates to choose from. You can also create your own customized template.

Thanks to standardized modules, all product information is divided into pre-determined sections. This means that it’s not just faster to make a tech pack with PLM, it also helps you store all current and future product data in a standardized manner. This keeps your brand’s identity and brand standards consistent, which eventually makes it easier for manufacturing partners to understand your directions.

4. Improved communication

A Tech Pack created in PLM can be shared with anybody via email and can also be accessed at any time by anybody having access to it. You do not have to rely on any third party to send the email and then keep track of all the emails sent back and forth. You can also add comments on each module / section and have your discussion with other users on it.

PLMs make it easier to get an overview of each item, which can be filtered according to season, style number etc. This helps reduce delays, improves communication and keeps projects on track.

5. Better consolidation and tracking

Excel sheets do not allow you to group information into categories and show these categories as tabs. With tech packs in PLM, you can easily view all related information pertaining to a fabric, color, sketch etc. in one tab. This enables you to consolidate materials usage across product families and identify redundant materials, which can lead to cost savings.

You can go deeper and even add country of origin, supplier name as well as the purchase and selling price for each item within the tech pack for greater transparency into your production line. Overall, it’s much easier to track each style/product development process from concept to production in your PLM.

6. Save time with resource libraries

Adding measurements, color definition, product groups for every new product or variation can be a pretty hectic job to a tech pack in Excel. A huge advantage of using PLM for tech packs is having the ability to pre-feed libraries for materials, measurement templates, washing information, fits, color grading and more!

You can add your standard measurements for different products like one for coats, for jackets, for footwear and so on. So, when anyone wants to build a tech pack, all they have to do is pick the template from a dropdown menu!

7. Sample approval and management

As a designer, the biggest advantage of creating a tech pack in PLM is that it allows you to undertake the sample approval process for each stage of development. You can track first prototypes, pre-production samples and production samples from anywhere in the world with an internet connection.

The PLM makes it easier to effectively manage sample reviews, and integrate data from other systems and spreadsheets. This system also allows you to maintain a record of all samples created by all vendors over a certain period of time. The information on these samples can be accessed at all times by all people involved in the project.