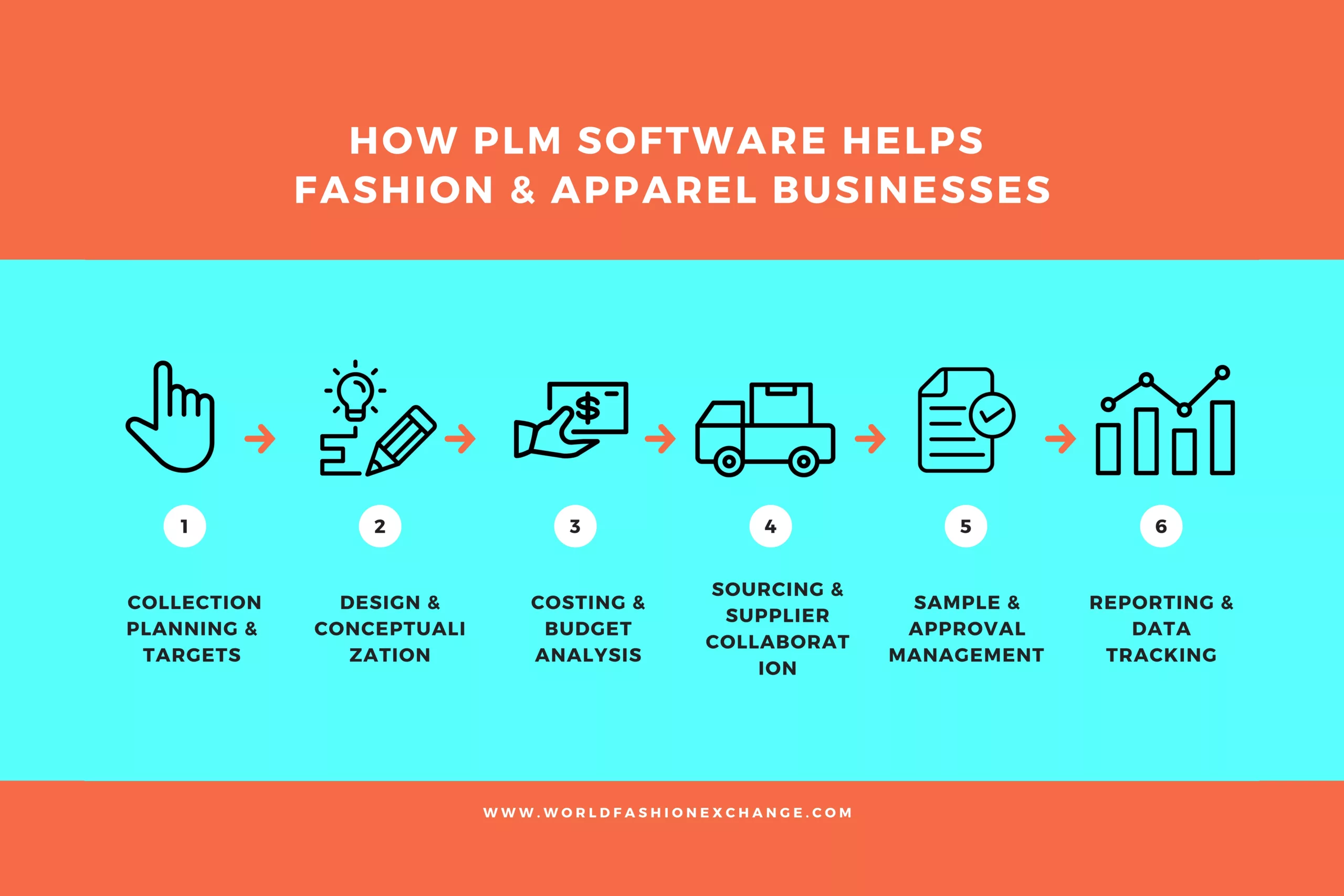

1. Collection planning and targets

To kickstart seasonal collections in the fashion industry, businesses have to set targets and create a line plan. This plan acts as a blueprint for the design, merchandising, and buying teams, outlining the number of styles to be developed—new designs vs. carryovers, color ways, quantities, prices, margins, and so on.

An apparel PLM solution helps companies define this plan, ensure adherence and share it with other departments, enabling a transparent and collaborative product development chain.

2. Design and Conceptualization

Design is crucial to the success of a product, and for fashion brands, it’s especially vital. However, manually building design data with spreadsheets, email, and files can be slow and tedious, leading to errors and delays. A PLM solution can shorten and streamline this process by enabling collaboration with team members and creating design briefs.

It helps you create products quickly with the help of pre-built blocks and by automatically reading designs from Adobe illustrator. PLM also ensures accuracy and ease of understanding in product specs, such as construction information, care labels, callouts, and bill of materials.

A key advantage of using PLM for design is that it shows visual snapshots and product details with all stakeholders in real-time as changes are made. This ensures that everyone is on the same page and can provide feedback or approvals as necessary.

3. Costing and budgeting

Fashion brands need to be able to quickly and accurately cost an entire collection and detail the buying and landed cost of each product. This includes defining margins and selling prices across regional markets, currencies, and sales channels (on-line vs. wholesale).

Many fashion businesses still rely on manual costing methods such as using spreadsheets with multiple columns that can be difficult to comprehend. This is highly error-prone and inefficient, often leading to calculation and margin mistakes.

Fashion PLM software provides pre-configured rules and values for accurate costing and allows specific team members to access only the cost components they need. Cloud-based PLM also allows vendors to directly enter costing data, saving time and money.

4. Procurement and supplier collaboration

Fashion buying involves figuring out how much quantity of each product should be purchased. This requires analysis of multiple implications such as budget, expected sales, vendor capability, vendor capacity, sustainability, quality, and customer expectations. It is a delicate balancing act and needs to be completed well in advance to leave enough time for production and distribution.

Using manual processes to define quantities (styles, colorways), vet suppliers, check compliance records, price and delivery negotiations, and so on is very time-consuming if done without PLM.

A fashion PLM streamlines buying and vendor management by centralizing procurement and purchase order processing and enabling easy collaboration with suppliers on-line. This offers greater visibility on purchase orders, shipment tracking, quality standards so buying is accurate and timely.

5. Sample and approval management

Sampling is a critical step in the pre-production process that involves several stakeholders, including manufacturers, designers, and developers. Samples typically undergo multiple iterations before being approved, and the product can move to production. The dynamic flow of information between design teams, developers, and vendors often located overseas and in different time zones can make this process time-consuming and expensive.

Fortunately, PLM provides a platform for all stakeholders to collaborate, streamlining the sampling process. This can reduce the cost and time required to get samples right and decrease the number of samples needed, saving time and resources.

PLM can significantly improve the sampling process by reducing the number of samples needed, shortening the time required to get samples right, and improving communication and collaboration among stakeholders.

6. Reporting and tracking

Personalized dashboards, alerts, time and action tracking, are critical to bringing efficiency to the product development process. A powerful PLM for the fashion industry integrates your departments and provides easy-to-understand metrics that enable quick decisions. This means teams are not wasting time manually putting together reports for meetings just to discuss the status of a collection or a specific product.

With customized dashboards, stakeholders have immediate visibility into the data they need for their specific roles, whether it’s senior management tracking overall progress, product managers monitoring specific collections, or the procurement team managing suppliers.

PLM eliminates the need for manually putting together reports for meetings just to discuss the status of a collection or product. Instead, teams have instant access to business data and can quickly make informed decisions without emailing, calling, or coordinating with people across departments, global offices, factories, and business units.