Navigating fashion waste requires understanding different recycling methods. Mechanical, chemical, and hybrid solutions each have their own benefits and challenges to help you make informed sustainable decisions:

Mechanical Recycling

Mechanical recycling involves breaking down textiles into fibers through physical processes like shredding and tearing. This method is effective for many types of fabrics, especially natural fibers like cotton and wool. However, mechanical recycling can result in shorter fibers, which means the quality of the recycled material often degrades compared to virgin fibers.

Mechanical recycling is ideal for post-industrial waste, such as fabric offcuts and unsold inventory, as these materials are often cleaner and have a more predictable composition compared to post-consumer garments. One significant limitation is the inability to separate complex blended materials, which limits the applicability of this method for mixed garments.

Chemical Recycling

Chemical recycling breaks down synthetic and natural fibers to their molecular building blocks, such as through depolymerization to convert polyester back into monomers. This method maintains fiber quality better than mechanical recycling and works well for synthetic fibers like polyester and nylon.

Enzyme-based recycling for cotton and other cellulosic fibers is also gaining traction. It uses enzymes to break down cellulose into reusable materials without compromising quality. Chemical recycling can handle some blended materials, making it versatile, but it requires significant energy and the use of hazardous chemicals. Additionally, the infrastructure is still developing, limiting scalability.

Closed-loop Recycling Systems

Closed-loop systems take materials from old products and reuse them in new products of equal or higher quality. These systems are effective when paired with robust take-back and collection programs, such as those implemented by brands like Patagonia and H&M.

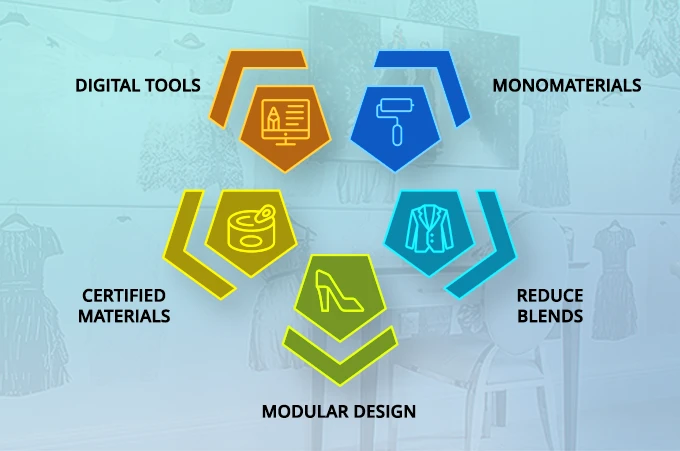

Closed-loop recycling works best for materials that can be chemically broken down and repurposed without losing quality, like polyester, which can be recycled multiple times. Brands using closed-loop methods focus on product design that facilitates recycling—using mono-materials, reducing mixed trims, and eliminating harmful dyes. However, they depend heavily on consumer participation and effective collection infrastructure.

Hybrid Recycling Methods

Hybrid recycling combines mechanical and chemical processes to optimize the recycling of complex garments. Initially, garments are mechanically shredded to a manageable size, followed by chemical treatments to dissolve fibers and separate materials.

This approach is especially useful for dealing with blended fabrics, which are difficult to recycle using traditional methods. Hybrid methods allow both synthetic and natural fibers to be reused independently. Although still experimental for many materials, hybrid recycling holds potential for making more textiles recyclable and improving fiber yield.

Automated systems for detecting and sorting different types of fibers before hybrid recycling are being developed to enhance efficiency and reduce labor costs.