The fashion industry has begun to adopt AI not only for efficiency but also for sustainability. By infusing artificial intelligence around design, planning, and production, brands can better utilize fabric and spend less on things they don’t need.

Let’s explore how AI is making a real difference across the fashion supply chain.

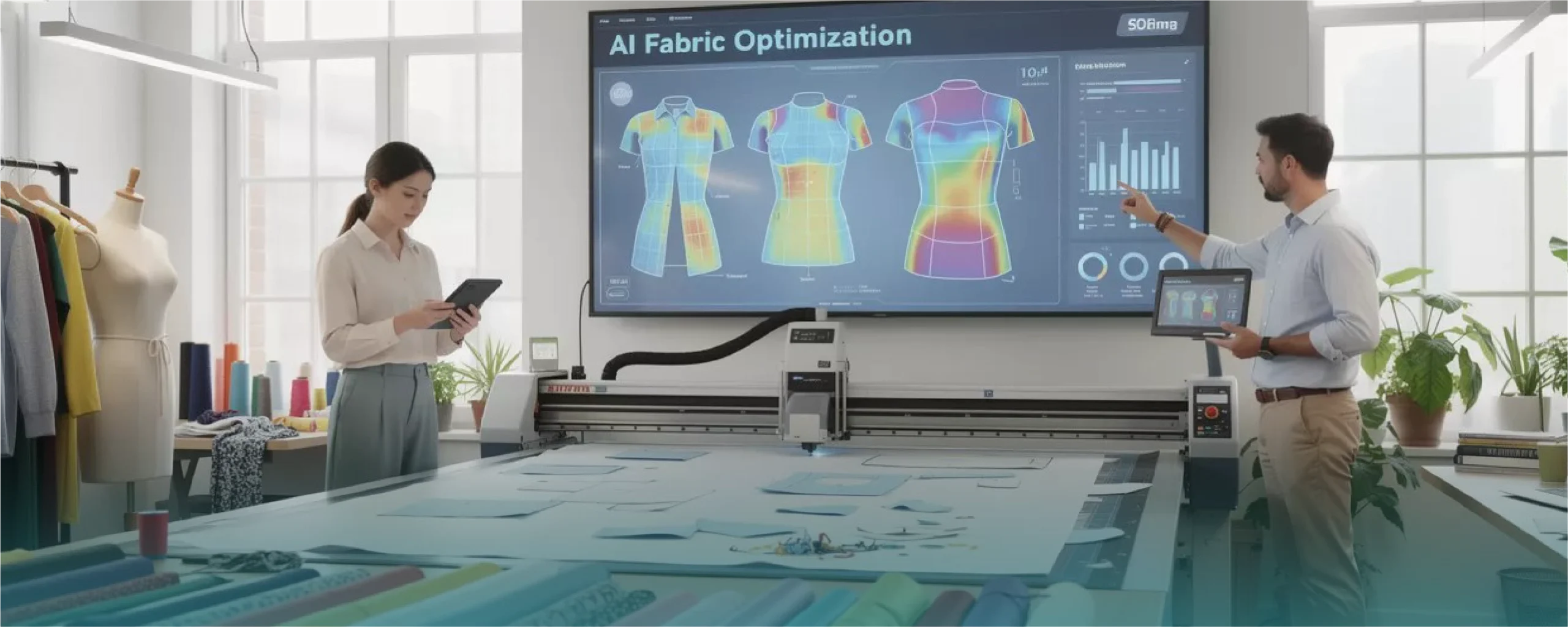

AI-Powered Design Optimization

The patterns were previously created using manual computation and trial and error, which left fabric behind. Now, thanks to AI-based tools, the design process is simpler for designers. They can make better choices right from the start. Designers using AI-based PLM systems, such as WFX Fashion PLM, see fewer sampling iterations and less fabric waste.

Here is how it works:

- Pattern Layout Optimization: It enables designers to create layouts that use fabric efficiently automatically. Thus, there is less leftover fabric and lower material cost.

- Predictive Fabric Usage: It suggests the best fabric width and how much to use for each design, so you plan better and waste less.

- Generative Design: AI tries out different design variations using minimal fabric. You will have the style you want while cutting scrap.

Smart Forecasting and Demand Planning

One of the largest sources of fabric waste is overproduction. AI assists brands in studying past sales, trends, and demand in specific regions to avoid excessive production of clothes. It aids the fashion and apparel sector in reducing waste and storage expenses.

Several artificial intelligence tools, such as ERP (Enterprise Resource Planning) and PPC (Production Planning and Control), are also used to enable brands to change the procurement and production schedules in real time. It entirely depends on the actual demand fluctuations or market trends.

Even an average-sized apparel company based on an AI-driven planning system has minimized the remaining fabric rolls by 15%. It emphasizes that smart forecasting may also lead to practical savings and sustainability.

Sampling and Virtual Prototyping

Designers using 3D sampling have the ability to design a virtual prototype that will give an idea of how the garment is going to be, how it fits, and how it will behave, giving a true preview of the garment before it is actually made. It reduces the need for making multiple samples.

Even AI-enabled PLM systems integrated with 3D design platforms help designers manage the entire virtual sampling process from design iterations to production planning within one streamlined workflow. It results in:

- Faster approvals and shorter development cycles.

- Less material wastage.

- Reduced environmental impact through fewer physical samples.

Production Planning and Fabric Cutting

Platforms like WFX Smart Factory or AI Planner make production planning and fabric cutting work together smoothly. By using AI for production planning and smart cutting machines, brands ensure the right fabric is used for each garment. This lowers waste, cuts leftovers, and speeds up the workflow. Also, it leads to:

- Optimized fabric use and cutting efficiency.

- Fewer material scraps and lower production costs.

- Smarter and faster production decisions.

Predictive Quality Control and Defect Detection

Fabric defects go unnoticed until late in the production phase. It creates unnecessary waste. AI helps spot issues immediately. Thus, brands using AI-powered systems can discover problems sooner and cut down material waste.

-

AI-Powered Cameras

How It Works: Scan fabric for defects in real time

Benefit: Reduces rejected materials

-

Machine Learning

How It Works: Learns patterns of defects to improve inspection

Benefit: Fewer reworks, less waste

-

Integration

How It Works: Works with Manufacturing Execution Systems (MES)

Benefit: Feedback loops improve supplier quality

Sustainable Sourcing and Circularity

AI helps brands plan smarter and reduce their environmental impact. It proposes the use of green materials and considers the sustainability measures of suppliers to make responsible sourcing choices. The tools work with the production data and predict possible deadstock. Additionally, AI-based traceability solutions allow brands to trace leftover materials through various levels of the supply chain. In this way, brands can reuse or repurpose any remaining fabrics prior to their disposal. Some AI traceability systems even have a perfect view of how the fabric goes through the supply chain, making reuse and resale easier.