AI enables brands to prepare better, produce, and maintain fabrics. Data insights help reduce waste at every stage, from start to finish. Here’s how it happens.

1. Smarter Design and Material Planning

AI tools in the early design phase help designers plan fabric use more smartly. These systems analyze historical data on fabric usage, pattern layouts, and production efficiency to improve efficiency. Moreover, designers using advanced Product Lifecycle Management (PLM) tools like WFX PLM system can:

- Visualize fabric use before cutting any material.

- Test virtual patterns and 3D samples to avoid multiple physical prototypes.

- Optimize cut plans to save every inch of fabric.

Thus, AI makes fashion brands more eco-friendly by helping them to use less off-cuts, produce less sample waste, and also reduce their design cycle, so that they can spend less on fabric and, ultimately, make more money.Many companies are also adopting AI for techpack automation at this stage.

2. Predictive Demand Forecasting

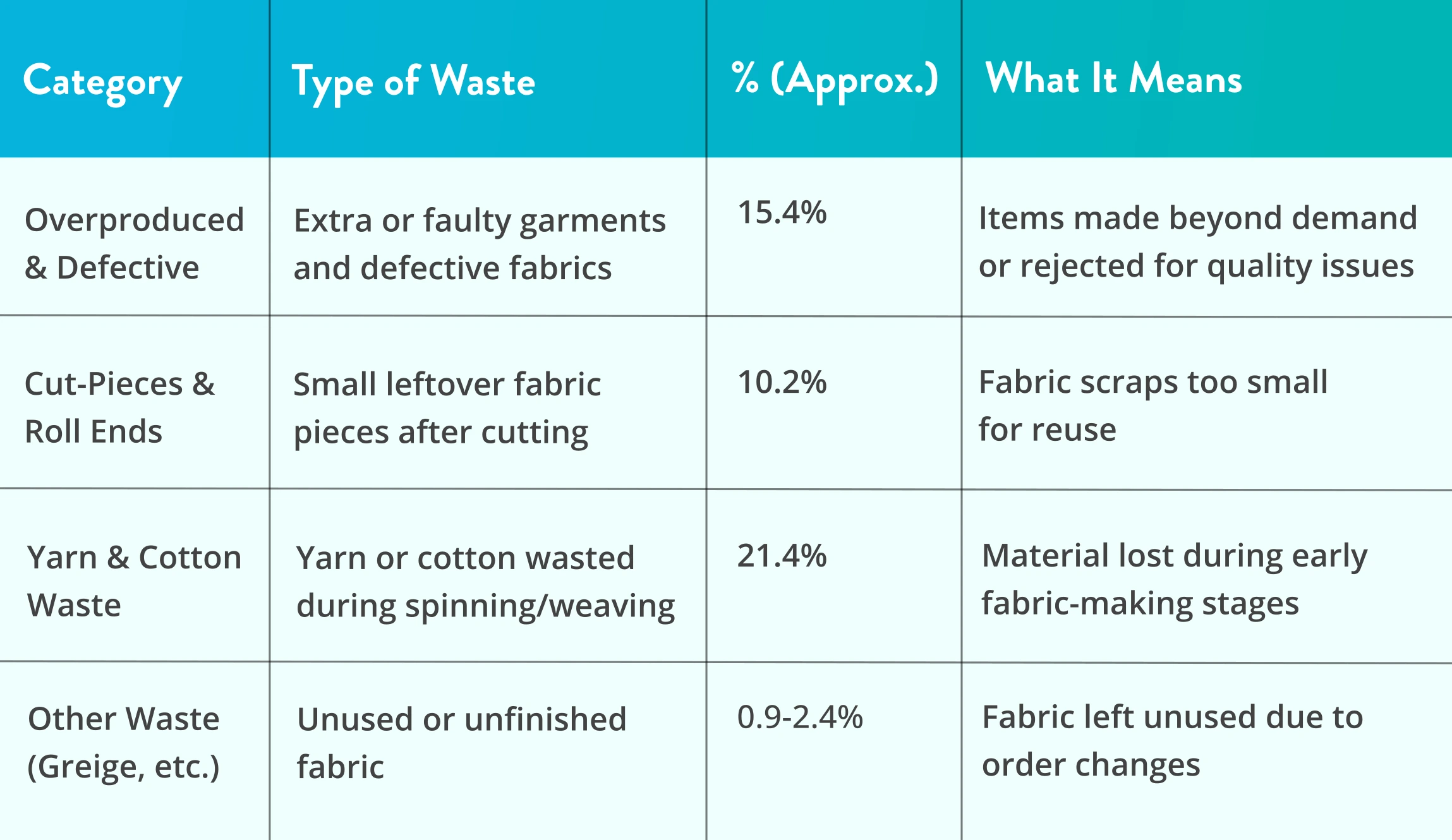

The main reason for fabric waste is the overproduction of garments. AI changes this by introducing predictive demand forecasting. Many brands now use AI-driven forecasting tools within PLM or ERP systems to plan production more accurately. This helps brands produce only what’s needed, saving tons of fabric that would otherwise go to waste. It looks at:

- Past sales data

- Current shopping trends

- Social media buzz

- Seasonal and regional demand

Hence, by forecasting more accurately, brands are able to produce closer to the volumes customers order. Brands save huge amounts of fabric, which is both a cost-effective and sustainable business practice by AI-powered fashion solutions.

3. AI-Enabled Cutting and Production Optimization

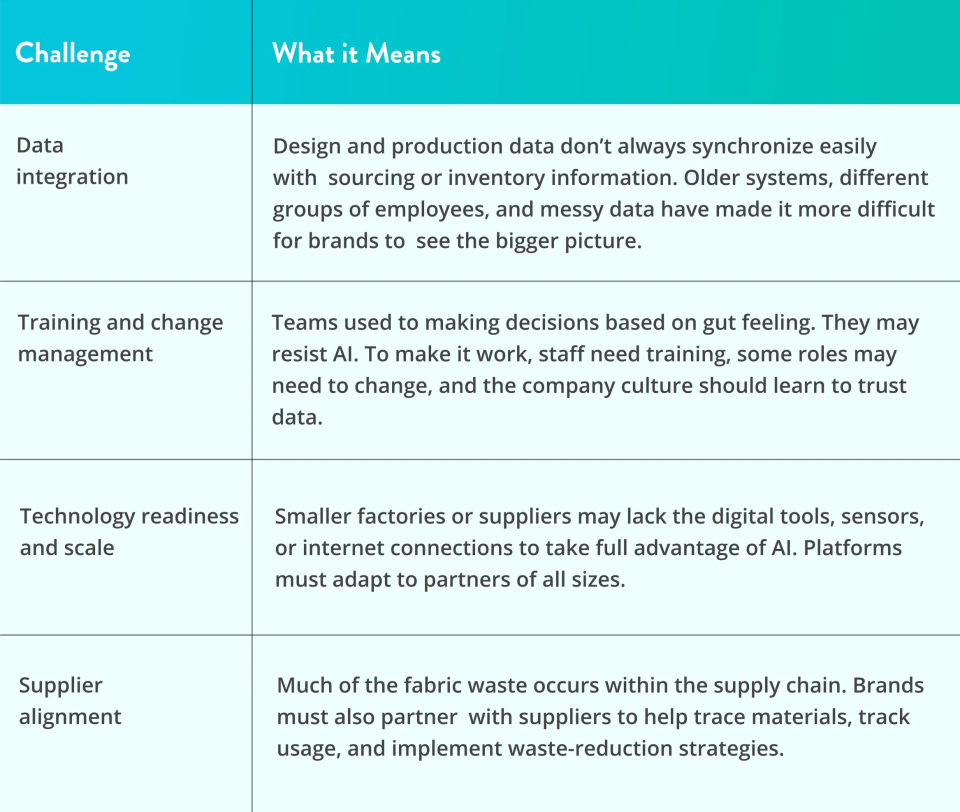

After design and planning, production is where a lot of waste happens, especially during cutting. Intelligent cutting algorithms calculate the most economical pattern pieces arrangement on fabric rolls, minimizing remaining scraps. With that said, AI-powered platforms such as WFX fashion PLM monitor and measure fabric usage across a multitude of suppliers to identify problem areas in the shortest possible time frame, bring efficiencies into the frame, and guarantee an economically sound use of fabric. It leads to less waste of the fabric, fewer errors, and more garment production from the same amount of material.This is another growing area of AI decision intelligence in manufacturing.

4. Waste Tracking and Material Reuse

Leftover fabric and off-cuts are often forgotten once production ends. AI-powered systems help here, too. It allows brands to log and track every leftover roll or scrap in real time. It also allows brands to understand what materials they still own and where the materials are stored. The designers can use such data to design new products or accessories out of those leftover fabrics rather than ordering new ones, supporting AI in sustainable fashion.

5. Sustainable Sourcing and Supply Chain Optimization

Fabric waste starts earlier with sourcing. AI helps sourcing teams choose the right suppliers and order the correct amount of material. It predicts how much fabric will actually be needed and flags potential risks of over-ordering. AI platforms can:

- Help management track suppliers performance and sustainability records.

- Ensure transparency in where materials come from.

- Plan fabric purchasing based on real demand and predicted production needs.

This, of course, improves supply chain efficiency and transparency and causes less harm to the environment.